It dropped into the mid-40s last night and the house cooled off proportionally. It starts getting light at 7 AM these days and cool mornings are just another reason to stay under the covers a little longer. I finally got up at 7:30 AM, got dressed to work, and made our morning coffee. After our breakfast of fresh mixed berries and homemade granola I turned on the fireplace and we enjoyed our coffee to its dancing light and warmth.

Chuck called to let me know he had set out one of his sheet metal nibblers for me to pick up at the shop. I left around 10:30 AM and drove Linda’s Honda Civic to Discount Tire in Howell. (My Honda Element is tied up at Brighton Honda until the middle of next week to get a broken driver-side door lock replaced.) I noticed last night while we were out that several tires on the Civic were under-inflated and the sidewalls were badly weather-checked. They still had plenty of tread but the paperwork indicated they were put on five years and 80,000 miles ago. Time for a change.

At Discount Tire the sales associate confirmed that the date code was from 2009 and corroborated my observations. The tread was probably good for another 20,000 miles but I do not mess around with old tires with cracked sidewalls. Michelin no longer makes the Defender, at least not in the P195/65R15 size, so I bought a set of four Continentals that should perform equally well and last for 90,000 miles. That means they will age out before the wear out, which is fine with me. It was going to be a two hour turnaround time so I texted Linda and Chuck and settled in to wait. Thank goodness for iPad games.

The technician pulled the car in at noon and a few minutes later asked me if I had the key for the wheel locks. I had looked for it earlier and not found it. He wasn’t sure he could get them off at all and would certainly ruin them in the attempt. That sounded like a bad situation getting worse so I had them set the tires aside while I took the car to Brighton Honda and had them remove the special lug nut from each wheel using their master key set. I bought a new set at the Honda dealership (so any Honda dealer can remove them in the future) and had them put those on and made sure I had the key when I left.

While I was there Rob gave me a quote on four Continental tires. The installed price, including a rebate in the form of a Visa gift card, was 30% lower than the price I paid at Discount Tire so I showed the quote to the guy at the counter when I got back. He said the quote was for a different, less expensive, discontinued tire. I had no way of knowing if that was true or not but he also asked if the guy who wrote me up gave me the rebate form for the tires I bought. I said ‘no’ so this guy printed out an extra receipt and gave it to me with the rebate form. That narrowed the price difference to 20% and I was satisfied with that. I liked the tires I had purchased and did not want to undo and then redo the sale. I have also had good experiences over the years with Discount Tire, including their nationwide free rotation and balancing policy.

When the tires were finally mounted, balanced, and installed I headed for Chuck’s shop in Novi. He was there when I arrived and had three different metal cutting tools laid out to show me. One was manual, one was electric, and one was powered by a drill. We decided that the manual one and the drill powered one were most likely to work for what I needed to do. He put them in a cardboard box along with cans of three different chemicals he was getting rid of. His trash, my treasurers.

On the way back to the house I stopped at the Shell station at Beck and Grand River Avenue to top up the fuel tank. I texted Linda and then headed for home. I arrived home at 3 PM to find lunch on the table. That was a nice surprise.

After lunch we uninstalled the desk in the bus and set the pedestals on part of a large blanket in the center of the kitchen floor. We draped the blanket over them and then uninstalled the hinged sofa seat and set it across the pedestals. We folded the blanket back over the seat and set the desk bases on top of it. We now had clear access to the wall behind the desk and the wall behind the sofa.

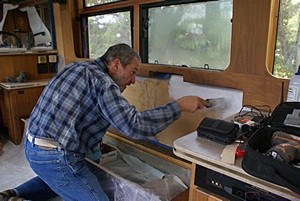

I got a 3″ brush from the basement and then got the Zinzer 123 Primer, opened it, and stirred it. It was still in good shape as it has been in the library since last fall when we repaired and repainted the west wall after Darryl was done installing the new HVAC system. Rather than pour it into another container I found a lid from a copy paper box to put it under the one gallon can. Linda finished masking off the woodwork and counters in the bus and then helped me spread painter’s plastic to protect the floor. We spread out an old bathroom towel, put the box lid on that, and then put the can inside the (upside down) box lid. I set the can lid aside and worked directly out of the can.

I started in the back of the hallway and primed the upper half of the outside wall as I worked towards the front. The lower half of this wall has vertical mirror tile wainscoting. We wanted to remove it but assumed the pieces were glued directly to the plywood wall, as they are elsewhere in the coach, in which case removing them would have done a lot of damage. We repositioned the plastic, towel, and paint and I continued up the passenger side priming the plywood next to and (mostly) under the windows. Completing that side up to the cockpit required one more repositioning of all the stuff. I was working in close proximity to the new living room captain’s chairs so we wrapped those in painter’s plastic as well.

I moved to the driver’s side and primed the area under the window and up the left side. Even though Linda had masked off all of the woodwork with painter’s tape I worked carefully and stayed away from the tape. We are not sure that the priming is even necessary and I did not want to risk getting any on the woodwork.

By the time we finished it was 5:30 PM and we were done working on the bus for the day. We had only worked for a couple of hours, and only accomplished a small task, but it was a critical path task that stood in the way of getting a whole chain of other important things done. Tomorrow we will sand the primer with 220 grit paper using the palm sander and try hanging the new wallpaper.

Linda made a pizza for dinner using the gluten-free almond meal recipe she got from Mara. She topped it with greens, onions, mushrooms, sun-dried tomatoes, and Daiya non-dairy cheese. There is also cheese in the crust along with garlic and other good things. We had a nice salad first with walnuts, beets, and sun-dried tomato vinaigrette. The salad was very good and the pizza was outstanding.

Philip Jarrell called to let us know he would be here at 8 AM tomorrow to start our French drain and driveway project, weather permitting. Detroit Public Television shows classic movies at 8 PM on Fridays and tonight’s selection was “Bullit” starring Steve McQueen and Jacqueline Bisset. We watched This Old House and a couple of travel shows after that and then went to sleep.