As I wrote in yesterday’s post we did not turn off the lights last night until almost 1 AM because we were keeping a close eye on the weather moving across the lower portion of Michigan’s Lower Peninsula. Although strong to severe storms were still forecast from 1 AM to 5 AM they either did materialize at our exact location or we slept through them. We had the house closed up and the air-conditioning on, so that cut down the sound level of outside noises.

A cold front had pushed through by sun up and we woke to a cool morning with blue skies and noticeably lower humidity. We did not have any trees, or even big limbs, come down and there was no damage to our brand new roof. The forecast yesterday was threatening enough, however, that in the morning we took the potted plants, and as much of our outside lawn furniture as we could find room for, inside including our sun umbrella and trash cans. I planned to be gone most of the day, and Linda was leaving mid-afternoon to go to dinner and a movie with Diane Rauch, so our first chore was to put all the lawn furniture, plants, and other outdoor stuff back outdoors.

This week is mostly being devoted to ham radio with the ARRL Field Day as the crowning event this weekend. My specific focus for most of the week, however, has been the “communications tower” adjacent to the east wall of our house. As described in previous posts we installed a cable entry box (CEB), mounted the cellular booster in the basement, mounted the inside cellular antenna, and ran coax cables. The antennas will (hopefully) be mounted on the existing 40 foot tower tomorrow, cabled into the CEB, and cables run from there to devices inside the house. With any luck by the end of the day tomorrow we will have decent cellular service inside the whole house, the ability to watch OTA TV programs on two different TV sets, and finally be able to connect one of our radios in the ham shack to an antenna. Today, however, was planned to mostly address other things.

I had an appointment with our dentist at 10:20 this morning and left at 9 AM. I planned to stop at Chuck’s bus garage and check that the key he lent me worked, but I needed gas for my car. I did not have time for both and did not really have a choice; I would have to check the key some other time. I ordered two cables yesterday from Scott (AC8IL) at Adams Electronics. Later in the evening I was unsure if I had specified the connectors correctly so I called and left a message. I called again this morning to make sure the message got through. It did, and my original connector specifications were correct.

I arrived at the dentist’s office about 10 minutes before my appointment time. I called Rick Short at Isringhausen USA to make sure he was going to be in before I drove two hours to Galesburg, Michigan after my dentist appointment. I got his voice mail a left a message. “ISRI” makes very high tech air suspension driver’s seats that are used as original equipment in motorcoaches, semi-tractors, heavy equipment, and locomotives. I would really like one for our bus, but it is not proving easy to get.

Dr. Steve and his assistant, Leslie, made molds of my upper and lower teeth and a bite impression. The molds will be used to make a mouth guard that I can wear while I sleep. Dr. Steve has a strong suspicion that I am clenching my teeth and the mouth guard will reduce or eliminate the irritation it causes. I will have to ask if I can wear it during the day too as I am occasionally aware of clenching my teeth while I awake.

I had not heard back from Rick by the end of my appointment so I called the main number at ISRI and talked to the receptionist. It turned out that Rick was not in today and she transferred me to Jeff Woodworth. Jeff was willing to meet with me but thought it would be a better use of my time to wait until Rick was available. My next opportunity to drive to Galesburg will be Thursday and I will likely go as the ISRI seat is holding up our ordering of Flexsteel seats through Coach Supply Direct.

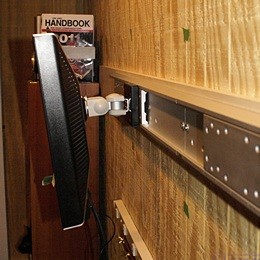

I stopped for coffee and then re-routed for Chuck’s bus garage in Novi. The key to the garage worked perfectly. I called Linda to let her know about the change in plans and headed for home. There is too much to do at the moment to waste much time so I installed the #4 AWG bare copper ground wire I bought yesterday at Lowe’s. I mounted an offset copper wire lug using the center support stud for the copper back plane in the CEB. I replaced one of the plastic hole plugs with a rubber plug with a small hole in the center. The hole I chose in the bottom of the CEB allowed the ground wire to come straight up into the lug.

Another view of the cable entry box on the east end of the house by the 40-foot tower showing the bare copper ground wire that runs to the ground rod and then to one of the tower legs.

Outside the CEB I routed the ground wire around to the existing ground rod and secured it using the new clamp I bought yesterday. There was an old ground wire connected from a clamp on the tower to the ground rod. I removed that wire along with some coax and control wires that I had clipped when we removed the old satellite dish. I then attached the new ground wire to the clamp on the tower. While we were at it Linda trimmed back a small bush that was growing between the tower legs and I pulled leaves, grass and other stuff out from around the Day Lilies that we transplanted last year around the tower base.

With the CEB grounded we looked at how we might get a video cable up to the TV/monitor in our bedroom. The wall where the TV is mounted has a hot water baseboard radiator that comes almost to the trim on the door wall. That end of the radiator has a copper pipe that goes through the floor into the basement and it was easy to locate the pipe in the basement. I determined that there was enough space behind the pipe to safely drill a hole but I had to drill it from the top side at an angle. A 5/8″ wood boring drill bit created a hole just big enough for the molded F-connector on the end of the cable to pass through.

We fed the video coax cable above the suspended ceiling in the ham shack area to the location of the hole. I then fed the cable up from the basement as Linda pulled it up into the bedroom. We adjusted the amount of cable in the bedroom to allow the wall mounted TV set to move through its entire range of motion. The other end of the cable was then routed into the sump pump room.

By the time we finished pulling this cable it was 3:30 PM and time for Linda to leave to pick up Diane. They were headed to Royal Oak for dinner and a movie as the movie they wanted to see was only showing at the Royal Oak Main Theater.

While I was out during the morning Lynch Carpet had called to let us know our Armstrong vinyl tile was available for pickup so after Linda left I closed up the house and went to get it. The 12 boxes of tiles, container of vinyl adhesive, and container of vinyl grout were all neatly arranged on a small pallet and tightly wrapped in shipping plastic. Rather than break this down and load each thing individually they used a fork lift to set the pallet in the back of my Honda Element. The rear suspension settled at least two inches when they transferred the full weight of the pallet to the floor of my car.

When I got back to the house I backed the car up to the garage. I cut the shipping plastic loose and unloaded the tubs and boxes of tiles. I put the pallet on the garage floor and then neatly stacked the boxes of tiles on it to keep them off the floor. Each box contained 14 tiles measuring 16″ by 16″ for a total area of 24.89 square feet. The Armstrong Alterna tiles are a “luxury vinyl” product, and are about 1/8″ thick. Even so, the boxes were heavier than I expected so I decided to weigh one. It tipped the scale at just under 42 pounds. That meant the entire pallet weighed close to 500 pounds, and, ignoring the weight of the cardboard box, that is about 3 pounds per tile.

When I drew out the design I determined that I would need 158 tiles, some of which would be partial. Figuring conservatively at 150 full tiles equivalent, and ignoring the weight of the underlayment, adhesive, and grout, the floor tiles will weigh about 450 pounds. I have no idea what the carpet and ceramic tile that I have removed weighed but the tiles were heavy. I also have no idea what the furniture weighed that we have removed but also have no idea what the new furniture will weigh. The intent was that the new floor and furniture would weigh less than old stuff but we will see.

I traded phone calls with my dad and we finally got to talk for a half hour starting at 4:30 PM. He turned 90 this past Sunday. Mike Fearer from Bid-Rite Concrete called at 6 PM and arrived about 10 minutes later to discuss the foundation for our 70 foot ham radio tower. I had printed off a page from the Universal Tower website showing their tower base. I also downloaded and printed their base and tower installation instructions. I had a set of these to give to Mike so he would have some idea of what the project is about. We looked at the proposed location for the tower and access for his dump cart. We also talked about the base, a rebar cage, a form around the top of the hole to allow the concrete to be slightly above ground, and a jig to make sure the base is level and the tower is plumb.

He said he was interested in the job and would work with me and Phil Jarrell (the excavator) to get it done. Rather than bid the job he would just do it for time and materials. He also said the current price of concrete was about $100 per cubic yard. We will need about six (6) cubic yards to fill the required 5′ x 5′ x 6′ (deep) hole. He thought he might be available the middle of next week but I don’t think I could have everything pulled together that quickly.

After Mike left I went to Lowe’s and picked up five 40 pound bags of topsoil, a 1-in/2-out signal splitter (rated for 5 MHz to 2.4 GHz), and a plastic snap cover channel for hiding the video cable we ran up into the bedroom from the basement for the TV set. I then went to the Meijer’s supermarket just across Grand River Avenue for soy creamer but they did not have what I was looking for. As long as I was there I had a salad for dinner at the in-store Subway.

While I was sitting there I called Mike Sharpe (W8XH) to confirm that he was available tomorrow to help with the antenna installations on our 40 foot tower. I mentioned that the only thing I lacked was a standoff with a pulley at the end of it for hoisting stuff up to me. He suggested that something like that was essential and I agreed, so I headed back to Lowe’s to see what I could figure out. What I ended up with was a three foot long 7/16-14 threaded rod, a pulley that had a closed eyelet on top (and was big enough for the 3/8ths rope I bought), some 7/16ths washers, and some 7/16-14 nuts.

When I got back to the house I unloaded the topsoil near the part of the east yard that needs to be filled in, took the other stuff inside, and then assembled the threaded rod pulley system. I secured the pulley on one end of the rod using two of the nuts, one on either side of the eyelet. I threaded a nut onto the other end, put on two washers, two nuts, two more washers, and another nut. I ran the first two nuts, with two washers between them, part way down the rod. I left the second pair of nuts, with washers between them, near the end of the rod.

I took the assembly out to the tower and adjusted the position and spacing of the two pairs of nuts and washers so they would bracket two of the horizontal tower members. In use I will secure the rod to the tower at each pair of nuts/washers using plastic cable ties. This arrangement will put the pulley at least 18″ from the tower which should be far enough out that we can hoist the DB8e OTA TV antenna to the top of the tower without it banging into the tower or hanging up on something. This antenna is the largest thing we need to hoist up. The old TV antenna is considerably larger and heavier, but it is coming down via gravity.

There was a message on our answering machine from Linda’s sister, Sr. Marilyn, who lives in St. Louis. She was listening to the news earlier today about the storms that went through our part of Michigan and wanted to make sure we were all OK. By the time we finished talking it was dark and I was done working for the day. Linda called shortly thereafter to let me know she was on her way home and I mentioned the call with Marilyn.

I finally opened the box with the vertical omnidirectional outside antenna for the cellular booster system and discovered that I should have opened it sooner. The mounting bracket was designed to be mounted to a vertical surface, such as the side of a house, not a tube, such as a tower leg. I did not want to postpone tomorrow’s tower work so I will have to get up early and figure out a way to adapt the existing bracket so I can mount the antenna to the top of the tower.

My initial thought was that an aluminum U-channel of the correct size might solve the problem very nicely. I could drill two holes in the bottom of the “U” to match the two holes in the bracket. I could then drill three pairs of holes through the sides of the channel. The antenna would be bolted to the bottom of the channel. With the open part of the channel held against a vertical tube I could secure it with three long plastic cable (zip) ties. Conceptually it should work and be easy to fabricate, but will take time which I won’t have a lot of in the morning. We have to get the two coax cables from Scotty (AC8IL), drop off my car at Brighton Honda for its 100,000 mile service, and be back in time to have the mount fabricated and all of the antennas and tools ready to go by 10:30 AM when Mike shows up.

Linda got home at 9:45 PM, earlier than she thought she would when she left. She and Diane ate at Luigi’s and had a very nice meal. They also enjoyed the movie. We had a big day on tap for tomorrow and we asleep by 10:30 PM.