Blog Post for July 2023.

This post consists of 18 photos with captions. It covers some additional electrical work in the barn, along with setting up shelving in the store room, moving stuff from the garage to the barn, fixing the screen doors on the house doorwalls, and hanging out with family.

Our youngest grand-daughter (SRF) with her dad sitting on the hearth of our fireplace. (Photo by Linda)

Our middle grand-daughter (MEF3, right) and daughter (MEF2, left) at our house. Bruce’s mom was MEF. (Photo by Linda)

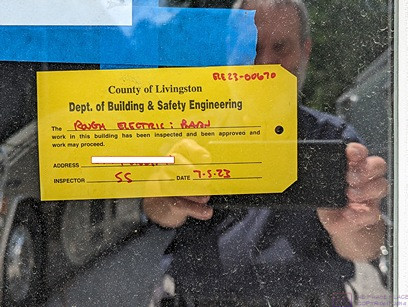

Bruce snaps a self-portrait with the approval tag for the rough electrical inspection on the barn. No changes were needed. It’s just a yellow piece of cardstock, but it was a big deal for him and a significant milestone for the barn project.

Linear LED light fixtures installed in the barn shop. Light switch in the white outlet box between the door and the subpanel. Bruce worked out the lumen calculations for a detailed work area ahead of time and these fixtures appear to produce sufficient light intensity with a daylight white (5000K) color temperature. As shown, they are installed in every other joist space—three in some and two in others (alternately)—which distributes the light nicely and protects them from physical damage. More fixtures could be added in the unused spaces if needed in the future. Note that the underside of the storeroom floor is the visible ceiling in the shop, and is painted white along with the joists and all of the walls. It’s a well-lit space. Note also that there is no insulation between the shop and the storeroom above. By design, the electric heater in the shop should also provide enough heat to the storeroom to keep it above freezing in the winter. If needed, Bruce will cut in a couple of floor vents to allow air to circulate, and possibly add a fan to one of them to draw cold air down from the storeroom to the shop. Winter 2023-24 will be a test to see what else, if anything, is needed.

It did take very long after the rough electrical inspection to complete the work needed for the final inspection. Again, no corrections were needed, and the work was approved. Here is the final electrical inspection approval tag (left) along with the rough electrical inspection approval tag (right). This was a major milestone for the barn project, and the culmination of a lot of work that included planning, specifying, purchasing, and installing many different components.

Although we did not yet have our Certification of Occupancy (CoO), we needed to start getting some things out of the garage. The Ford F-150 has been an excellent vehicle for us, providing excellent passenger comfort, great performance and fuel economy, and a lot of very versatile utility, including hauling things, towing our trailer, and being equipped to tow behind our bus.

There was still a lot of stuff in the garage, but a space was starting to appear where we could get Linda’s car inside. Much of what is visible in this image, including the plastic shelving units, will get moved to the barn, some in the storeroom, some in the shop, and some in the RV bays (but not too much). Some of it will also end up in the shed.

Our youngest grand-daughter shares a bench with a couple of book-reading statues at the local public library.

The local public library as a great children’s room that includes this reproduction tree truck and with child-sized hollow. Our youngest grand-daughter seems to fit in this space just right.

By this point in July 2023, we still had a lot of work to do to get the shop and storeroom in the barn set up to use efficiently. The heavy-duty Kobalt metal shelving is set up on the front and rear walls of the storeroom. The shorter east and west walls will get some of the full-height plastic shelving units from the garage. The table in the center of the room is temporary, and will be replaced with shorter (3-shelf) plastic shelving units and capped with a sheet of plywood or other suitable counter-top surface.

It might not look impressive, but we could not ever recall getting two vehicles in this garage since we bought the house 10 years ago.

This little device might not look like much, but it is an important part. It’s the combination roller / height-adjuster for the screen doors on our house doorwalls. The doorwalls (and Windows) are Renewal by Andersen, and I could NOT find these adjusters at any of the local big box / hardware stores. We found this one in the garage, left behind by the previous owners. With the part number in hand, I was able to order additional ones. We have five (5) doorwalls, each screen requires two of these devices, and most of them were broken or just plain worn out, and needed to be replaced.

Plastic shelving units in place along the east wall of the storeroom in the barn. And yes, we are putting things on them because we have to. But everything in this storeroom will be reorganized once all of the storage units are in place. Really, it will. Promise.

The west wall of the barn storeroom, with plastic shelving units in place. A unit with parts bins will eventually occupy the space by the door.

The barn shop looking east from the west wall. The band saw (left) and drill press (far end) are positioned in front of the two windows where wall storage isn’t possible. Both of these will eventually be mounted in/on custom designed/built workbench/storage units.

The National Electrical Code requires a clear space in front of load centers and other electrical equipment that require access for facility operation and maintenance. Minimum depth, width, and height of this space is specified. Bruce has taped out this area on the floor for the main load center, but will eventually mark it permanently with paint or more durable tape.

What’s good for the goose is good for the gander. The sub-panel in the barn shop gets the same “no go” floor treatment as the main load center. It might seem silly, but we will be moving a LOT of stuff around, and it’s just too easy to forget that we can not store anything in these spaces.

And last, but not least, for this month, work begins on replacing the roller / height-adjusters on the doorwall screen doors.

…