This post covers October 1 – 7, 2014

2014/10/01 (W) Aqua-Hot (Plus)

I woke up this morning sometime between 7:00 and 7:30 AM and worked for a while in the bedroom. By 8:30 AM I heard voices, which meant Butch and Fonda were up and dressed, so I emerged from the guest bedroom to see what the plans were for the day. I knew they would involve trying to fix our Aqua-Hot diesel-fired hydronic heating system, but I was not sure exactly how that work would proceed.

The first task, however, was to have breakfast. Granola with fresh blueberries, red raspberries, and blackberries, plus orange/grapefruit juice and coffee. Ahhh, coffee. I did not get any yesterday, so I enjoyed having some this morning.

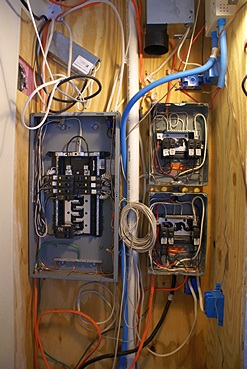

Butch & Fonda’s Aqua-Hot in a bay of their MC-9.

Sometime between 9:30 and 10:00 AM Butch and I got to work on the Aqua-Hot situation. We tried firing up my unit multiple times but it would not ignite and we had no evidence of fuel getting to the nozzle. Butch added water to his unit and fired it up just to verify that it worked. We unplugged the controllers from both units and connected my controller to his unit to see if the controller was the problem. It wasn’t; his unit ran fine with either controller. We put his controller on my unit, just to check, but the unit still would not ignite.

We decided that the most expedient course of action was to simply install his burner in my unit. That was the point at which we realized that our units are not identical. Ours is an AHU-103-000, originally made in the late 1980’s and early 990’s while theirs is an AHE-100-02s (?? check this). The differences are minor but important, namely:

- the fuel connections into and out of the burner are not the same so our fuel lines would not connect directly to their burner.

- their burner had two fuel lines that ran down to bulkhead connectors while our unit did not use bulkhead connectors.

I had agreed to buy their entire Aqua-Hot to use for spare parts, so we started by removing the burner from our unit and setting it aside. My plan is to repair it eventually or disassemble it for parts. The problem is that I suspect the fuel pump and/or fuel valve and/or fuel valve solenoid are defective so I would have to determine whether that is the case.

Removing our burner was a bit more complicated that we thought it would be. Besides the fuel lines, which had to disconnected and plugged, we had to disconnect a wiring harness that had four wires running into the main boiler box for the temperature control thermostat and over-temperature safety thermostat. These wires were terminated in female spade connectors pushed on to the male spade lugs on the thermostats. Rather than try to feed them through the small hole in the case I made a diagram of which color wire went where and then cut the connectors off allowing the wires to pull out easily. We had to repeat this procedure on Butch’s burner. Quite a bit of diesel fuel leaked out of various fuel lines and I kept soaking it up with paper towels. With our burner out of the way we evaluated the situation and decided to take care of two other issues before proceeding with the Aqua-Hot. That’s how it goes with bus projects.

The first issue was the check valve on the Parker FPM-50 Fuel Polishing Module installation, which had been leaking at the gasket between the two halves of the body since I had redone the fittings and reinstalled it. I had a new (unused) check valve that I should have installed when I redid the fittings, but I didn’t. The fuel line on the inflow side of the check valve was already loose so we disconnected the other end. That allowed us to work in the shop with a vice to help hold parts. We removed the fittings from the old check valve, cleaned them up, and assembled them to the new check valve using pipe thread compound rather than Teflon tape. We then reassembled the new check valve assembly back into the FPM-50 system. We turned the FPM-50 on and did not have any leaks; finally.

The second issue was related to the fresh (potable) water plumbing. When we purchased the coach five years ago the fresh water system had two 12VDC water pumps plumbed in parallel with independent shutoff valves for the input and output sides of the pumps. The system also had a surge tank. Last spring (or fall?) I had replaced these two pumps with a single Shur-Flo 4048 model, removed the surge tank (which was not needed or recommended for the 4048), and used flexible hoses and various adapters to get the new pump connected in to the existing plumbing, including plugs to seal unused fittings. That left a lot of plumbing in this part of the bay (just off the end of the Aqua-Hot) that did not perform any useful function and was in the way of other things, like the FPM-50.

All of the original plumbing in the coach is Quest, which is no longer made. After studying the system for a while Butch realized that that Quest tubing at the valve on the end of the outlet hose had to be connected by being slipped over a barbed fitting and tightened with a swaged band. If we could cut the band and get the fitting out of the tubing we could cut a different section of tubing, allowing us to remove all of the unnecessary plumbing, reinsert the barbed fitting into the cut line, and put a clamp on it to seal it. Butch had a special tool for clamping bands on PEX tubing and it appeared that the bands were a compatible size for the Quest tubing. He also had his tubing cutter handy, so we removed the band (which was copper and easily cut), and proceeded as just described. The PEX band swaged down nicely and passed the “Go /No-Go” test (a special tool that gages the clamped band to ensure it is tight enough without being too tight).

We turned the water pump on and had a leak at the plastic double-ended male nipple between the end of the hose and the Quest fitting. With the pump off Butch removed the hose and then the nipple. It was cross-threaded but the threads were OK. Both the hose and the fitting are sealed by rubber gaskets anyway, not by the threads, so I reassembled the three pieces snug but not over tight. I turned the water pump on (up in the house portion of the coach) with Butch watching for leaks and we did not have any. It was shaping up to be a very good day.

With those two issues resolved, and lots more room to work on my Aqua-Hot, we removed the bulkhead fittings from Butch’s unit and cleaned them up with a wire brush wheel in his shop. Butch reassembled some of the parts in the shop with pipe thread compound and I installed them in two unused bulkhead holes in our unit. I then threaded in the two final fittings on the outside of the unit and had Butch do the final tightening. He is stronger than I am, and very experienced at working with this sort of technology, so he has a good feel for how tight things need to be and can make them to correct tightness.

It was finally time to install their burner in our unit. I stripped the ends of the wires that go into the burner box, set the burner roughly in place, taped the wires to a piece of plastic banding, and fished the wire harness up into the boiler box. Butch installed the new female spade connectors onto the wires while I was doing something else, but I do not recall what it was. I installed the connectors onto the mating pieces on the temperature limit switches. (Because of the way my Aqua-Hot is installed I have to work bent over at the waist. This is very hard on Butch’s back, and by the end of the day my back was a bit sore and stiff as well.)

The burner assembly is held against the combustion chamber by two captive bolts that swing into position. The bolts have flanged nuts on them that tighten down and hold the burner snug to the boiler. Because our unit is installed “sideways” it is very difficult to see and reach the nut on the lower back side of the burner. The nuts are 10mm (Webasto is a German company) and a ratchet with a 10″ extension is needed to reach them. I found the best way to attach the burner was to hold it in position with my left hand, get the upper/outside bolt in position with my right hand, and then run the nut down with my right hand, but not too tight. I continued to support the burner with my left hand while I reached over the top to find the other bolt by feel, flip it into position, and tighten the nut enough to keep it from slipping off.

I knew I had to be very careful with these bolts as over tightening them can crack the mounting flange on the combustion chamber; a big mistake. I held the burner with my left hand and made sure it was fully and properly aligned with the combustion chamber flange and then alternately snugged the two nuts down. The specifications on these nuts is for “20 to 40 inch-pounds.” That is not a lot of torque. Butch had a really good digital readout torque wrench, but it only went down to 60 in-lbs, so I had to guess.

With burner re-installed, Butch attached the two burner fuel lines to the appropriate bulkhead fittings. These are flare connectors so they did not use pipe thread compound. I then attached the supply and return fuel lines to the appropriate fittings on the outside of the bulkhead connectors. These were barbed fittings that the rubber fuel lines slipped over and were secured with band clamps.

We turned the unit on (in the coach) but it did not fire. One concern, which I will remedy tomorrow, was that the level of fuel in the tank might be close to the lower end of the pickup tube for the Aqua-Hot. These tubes are usually installed so that accessory devices, like heaters and generators, cannot use the last 1/4 tank of fuel, ensuring that there is fuel available to start the main engine and travel a reasonable distance (to get more fuel). It took three tries to get it to ignite and when it did it produced a lot of white smoke, which is unburned fuel.

While the unit was running Butch checked the exhaust leak and said it appeared to be under the coach, not up at the Aqua-Hot itself. That was a lucky break and big relief. The beginning of the exhaust pipe slips over a pipe thread nipple that is threaded into an elbow and is secured with an exhaust pipe clamp. Butch saw telltale streaks of black soot indicating that exhaust gases were leaking out at this point. We shut the unit off and let it cool down enough that I could remove the pipe clamp securing the exhaust pipe to the nipple. Both bolts were very rusty, and did not come off easily, but I got them off. Butch had one clamp of the correct size on-hand so I installed it. I will get a second clamp tomorrow when we go to town, plus a replacement if a Butch wants one.

We turned the unit back on and again it did not want to ignite. Butch though it was a fuel delivery problem, such as a loss of prime, or perhaps air was getting into the line. After a couple of attempts I turned the Parker FPM-50 on and let it run for a while, thinking that it might re-prime the line. I turned it off after 10 minutes and turned the Aqua-Hot on. It went through a long pre-combustion purge stage and then finally ignited. It produced copious amounts of white smoke initially, but after 10 minutes there were no visible exhaust fumes. Butch is suspicious of the FPM-50, either the unit itself or the installation, but I have run the Aqua-Hot successfully many times subsequent to its installation until it failed to fire this summer. Clearly the situation requires further investigation which will happen tomorrow or Friday, depending on the weather.

The unit heated up fully and shut off automatically after which I turned it off. I then mounted my burner onto Butch’s combustion chamber, both to protect it and to make sure some small animal did not take up residence in the combustion chamber. The only thing left to do on our Aqua-Hot was to mount the new Oasis expansion reservoir. We determined that we could mount it to the side of the unit with short sheet metal screws. I held it in place and marked the hole locations, center-punched them, and drilled the out using a bit that Butch gave me. The housing is stainless steel and was difficult to drill even though it was thin. I had 1/2″ screws and Butch found some washers. It took some fiddling, but I finally got it attached through all eight holes. We will switch the overflow tube from the undersized reservoir that came with the coach to the much larger Oasis reservoir tomorrow after the unit has cooled down overnight and drawn most (all) of the coolant back into the boiler. I put the cover back on the burner end, we put our tools away, and called it a day. And a good day it was.

Butch’s brother, Tom, and his wife, Tracey, came over during the late afternoon. It was 7 PM by the time we were done working, so we got cleaned up (sort of) and drove down to the Old Mill Restaurant just west of town on SR-16. I had a small pizza, no cheese, with onions and mushrooms. They made the crust thinner than their usual and it baked up very nicely. Once we got back to the house I worked on this post while Butch dealt with e-mail and Fonda worked on the wedding dress she is making for their daughter Jean, who is getting married just before Thanksgiving. After we turned in for the night I off-loaded all of the photos I took of our day’s work and then went to sleep.

Our Aqua-Hot in a bay of our Prevost H3-40.

2014/10/02 (R) Aqua-Hot (Or Not)

I was up at 7:30 AM and fixed breakfast in the coach at 8; granola with fresh blueberries, red raspberries, blackberries, and almond milk. A glass of orange/grapefruit juice, but no coffee.

Butch and I left at 9 AM to run errands in Logansport. He stopped at a filling station that sold kerosene and bought four gallons. I will explain why later. I got a big cup of coffee there and it was a decent brew. Our next stop was NAPA Auto Parts where I bought a 1.75 inch exhaust pipe (muffler) clamp and Butch picked up some things he had ordered. Next stop; Rural King. We do not have this chain anywhere near where we live. It’s a kind of hardware, sporting, and home goods store that carries an interesting assortment of items that might be of use to farmers. It’s not a fancy store, but it carries a lot of stuff and is well organized. Butch needed some carpet tacks and I bought a fruit fly trap and an insect fogger. Rural King also has free popcorn. (Now you know the real reason we stop there.) I got some on the way in and on the way out. 🙂 Our last stop was at Aldi’s where Butch picked up some things they needed for their dinner tonight.

When we got back to Twelve Mile I changed clothes and got to work. The weather forecast was for rain and warm temperatures. Rain had already wet the pavement around the buses so Butch gave me a large sheet of corrugated plastic to lie on while I installed the muffler clamp on the Aqua-Hot exhaust pipe. I installed it next to the one I put on yesterday but pointing in the opposite direction. These clamps are just “U” bolts with a matching saddle that completes the other half of a circle when slipped over the U-bolt and tightened with the nuts.

The Aqua-Hot had cooled off overnight and suctioned all of the coolant in the expansion reservoir back into the boiler. That allowed me to disconnect the overflow tube from the bottom of the reservoir with a minimum of mess and attach it to the main fitting on the new Oasis tank. I added a 50/50 mix of water and ethylene glycol antifreeze to the tank until the level was halfway between “minimum cold” and “maximum cold.” This should have been the final Aqua-Hot task, but it would not ignite when turned on even though it worked yesterday after the burner swap.

I removed the service cover and Butch and I started to puzzle out what the problem might be. When I turned the switch on at the dashboard the blower came on immediately but the fuel valve apparently did not open. We don’t know if the spark igniter was working, but the burner never lit and eventually the blower shut off. When that happens, the controller “locks out” the unit from even attempting to turn on again and I have to turn the switch off to clear the lockout and then turn it back on.

Butch had me disconnect the supply and return fuel lines on the outside of the bulkhead and replace them with clear fuel lines about 5 feet long so they would reach into the bottom of the kerosene container. (Remember the kerosene Butch bought earlier? Now you know what it was for. He will eventually use it to fuel a heater.) He thought we might have an air leak in the fuel lines/connections and the clear fuel lines would allow us to see the air bubbles. By drawing kerosene out of the container, pumping it through the unit, and returning it to the container we could recirculate it indefinitely as long as none of it was being burned. Even with combustion taking place most of the fuel gets returned as the unit only burns fuel at the rate of 1/4 gallon per hour.

With the kerosene setup we had taken the coach’s diesel fuel lines, including the Parker Fuel Polishing Module, completely out of the system. Butch suspected the FPM-50 might be the culprit and thus did not except to see air bubbles, but we did; a lot of them. And the unit still wasn’t firing. We were perplexed and a bit frustrated. On the other hand, it appeared that the FPM-50 was no the culprit, or at least not the only culprit.

Since his burner had always worked well in his unit we figured the problem had to be something in my unit. Butch got the service manual for his unit, which is almost identical to mine, and we started looking at wiring diagrams. The units have four thermostats; two for the diesel burner and two for the 120VAC electric heating element. We thought those might be the problem and checked the two for the burner but they were OK and appeared to be functioning correctly. There are also six fuses. I pulled and checked each one and they were also OK. When Butch works on his unit he often starts it by connecting a jumper wire across the two terminals for the switch wires to save himself the trip to the bus (where the switch is located) and back to the bay (where the unit is located). He connected a jumper wire across the switch terminals on my unit and it fired up after the normal 25 second purge cycle. It was good that it started, but not good that we did not know why.

We were still seeing a lot of air in the kerosene and Butch decided to remove the secondary fuel filter from its holder and change its orientation so the output was lower than the input, ensuring the outlet was covered by fuel. The air bubbles lessened considerably when he did this but did not clear up completely and the unit was producing a lot of white smoke (unburned fuel). It always produces some on startup until the combustion chamber heats up, so we decided to let it run. The exhaust fumes eventually cleared up and the coolant eventually expanded to within 1.5 inches of the top of the (new) overflow reservoir when the unit reached maximum operating temperature, automatically shut off the burner, and completed the purge cycle.

We wanted to cool it down so we could test it again so I removed the jumper wire to keep it from restarting. I then opened all of the coach windows, opened all three ceiling vents, turned the ceiling exhaust fans on high, turned the three Aqua-Hot house thermostats on, and turned them up to their highest temperature settings. I also turned on the engine pre-heat coolant circulating pump. As the unit cooled down it started drawing the coolant from the reservoir back into the unit. We turned the unit on using the switch at the dashboard and it fired up. At this point we had not found anything wrong and had not fixed anything, but it seemed to once again be working correctly. While the unit was heating up and cooling down Butch repaired a flat tire on a semi-trailer that they used to store parts for their business.

I still had the fan coil heat exchangers and the engine pre-heat running to cool the unit down. The power for these units, and for the coolant circulation pumps, is independent of the diesel burner as the Aqua-Hot can also be heated by an electric element and by the main engine. When the unit had cooled sufficiently I removed the temporary fuel supply line and reattached the supply line from the diesel fuel system. I left the clear fuel return line connected at the bulkhead. I removed the heavy rubber fuel line from the bottom of the FPM-50 check valve, cut the clear line to a workable length, and attached it to the bottom of the check valve. By leaving the section of clear line in place we would still be able to monitor for air bubbles.

After cleaning up diesel fuel that had leaked out of hoses and fittings I turned the burner on using the front switch. The unit immediately came to life and the burner ignited the way it is supposed to. We still had some air bubbles in the return line, but no worse than before until I moved the secondary fuel filter back into its normal horizontal position. That created a lot of air bubbles so I moved it back so the outlet was lower than the inlet. I am suspicious of this filter and/or the lines attached to it. The unit was working and there was no point in bringing it up to full temperature so I shut it off and installed the service cowling. It will be interesting to see if it ignites tomorrow morning when it is cold.

Butch and Fonda worked on uninstalling their Aqua-Hot while I unloaded most of the parts, supplies, and tools from my car and put them on a cart in their now mostly empty warehouse. As I was finishing it started to rain lightly. We quickly gathered up our tools, stowed our tool boxes, closed up our bus bays, and moved everything else into the garage. I shut off the ceiling exhaust fans, closed the vents, and then closed all of the coach windows. I shut off the three house thermostats and the engine pre-heat pump and then moved my car back to its usual parking spot. By that point it was raining harder.

Today was Fonda’s birthday but they did not have any special meal plans. Around 4:15 PM I decided to go fill the fuel tank on the coach. Gallahan’s Truck Stop is only 10 miles from their house and an easy run there and back on SR-16 and US-31. I arrived on Tuesday with only 3/8ths of a tank and I wanted to eliminate the main tank fuel level as a potential source of the no-fire problem. I was going to need fuel anyway for the trip to Elkhart and back next week and any subsequent movement of the bus. I texted Linda from the truck stop to let her know it was Fonda’s birthday and suggested that she call their house later.

Butch and Fonda had leftovers while I was out so I dined alone in the coach. I had a large green salad, some pretzels with hummus, and a tofu hot dog. Apple cider and reheated apple/pear crisp topped off the meal. Yum. I brought my dishes and cutlery in the house and washed them.

Linda called while I was eating so I did not get to talk to her. Butch was very tired and turned in early so I chatted with Fonda for a while about their various family members, many of whom I have met over the years, and what they were up to before retiring to my room to check e-mail and work on this post. Although not as productive as yesterday it was still a long and tiring one. Actually the days when you don’t feel like you have accomplished anything definitive are the hardest.

2014/10/03 (F) The Other Bus

I got up at 7:30 AM, got dressed to work, and then spent a half hour doing some preliminary packing. I had breakfast in the coach (granola with fresh berries) and was enjoying my first cup of coffee while cleaning up a few dishes when Butch knocked on the door. He was curious if I had tried starting my Aqua-Hot. I had not, so I turned on the switch for the diesel burner. The blower came on right away and then the burner ignited after a short purge cycle of perhaps 15 seconds. The combustion was clean on startup with no visible exhaust smoke. I checked the expansion reservoir and the coolant level had dropped overnight to the “minimum cold” reference mark. The unit was running well and I left it on to complete a full heating cycle.

When I arrived in Twelve Mile on Tuesday I noticed some small flies in the kitchen as I was setting up the interior. We had not used the coach since mid-June and had left a couple of windows slightly open to keep it aired out and prevent it from getting too hot. We did not turn the refrigerator off, which adds heat to the interior. The windows have screens, but the little bugs could have gained access through any number of places. I set up the fruit fly trap I bought yesterday to try and rid the coach of the little bugs.

I also bought a fogger yesterday that I had planned to use today just before leaving for home, but the directions said to only leave the fog for two hours and then ventilate the space. There were also cautions about removing/protecting food and cooking/eating utensils and eliminating ignition sources, including the refrigerator. The refrigerator (and freezer) are full of food so that was more trouble than I was prepared for today. I put dryer sheets in the cabinets under both sinks (kitchen and bathroom) and in the bay by the Aqua-Hot. We found several acorns inside the Aqua-Hot when I removed the service cowling on Wednesday and I have read that animals do not like these dryer sheets. The sheets cannot do any harm so there was no down side to trying this.

Our major focus today was two interior projects in Butch and Fonda’s bus, a 1987 MCI MC-9 Crusader II NJT (New Jersey Transit). Like most owner-converted buses, it started life as a seated coach in revenue service and got a lot of use over the years before being sold for a small fraction of its original cost. In the case of their coach the New Jersey Transit Authority ordered a large number of these MC-9 model coaches with special modifications for use as commuter buses, as opposed to a city bus or a tour bus. The MC-9 proved to be a reliable coach and used ones make an excellent but economical platform for a DIY conversion project.

They needed help installing a piece of “FRP” (Fiberglass Reinforced Plastic) on a section of wall. They have used this material, in white and almond, for wall paneling and as a ceiling headliner. The material comes in 4’x8′ panels and is flexible but durable. It brightens the interior, as it reflects light, and is very easy to clean. The piece had to be fitted, marked, and trimmed several times. This project occupied Fonda for much of the day, Butch for some of the day, and me for a small part of the day.

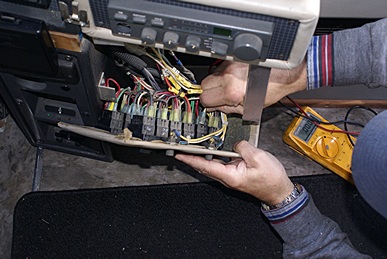

Butch & Fonda’s MC-9 conversion in the process of being wired.

The other project was electrical wiring for switched kitchen outlets and the ceiling lights in the kitchen and living room. I spent most of the day working on this. Butch had finally decided that I know enough about electrical work that I can be entrusted with these tasks. He is using Wiremold surface mount boxes and wire channels, which makes a lot of sense in a bus conversion where you cannot necessarily run wires through the walls of the bus.

Butch had previously installed Wiremold 2-gang base plates for electrical boxes to hold switches and outlets. We routed electrical cable (10, 12, and 14 AWG wire, both NM cable and separate conductors) between base plates and the AC power distribution boxes. I wired up outlets and switches and tied in lines and loads.

Larry “the scrap metal guy” showed up about noon so Butch had to use the forklift to load a pallet of old Crosley radiator cores into Larry’s truck. After Larry left Butch used the forklift to remove their Aqua-Hot from their bus. Fonda and I helped get it off the forklift into the back of my Honda Element after which we returned to our electrical and paneling work.

I quit working around 2:15 PM, changed out of my work clothes into something cleaner and more comfortable for driving, and washed up. I finished packing and then loaded the car for the trip home. I had planned to leave at 3:00 PM and pulled out of their parking area at 2:59 PM. I did not have lunch and would not be having dinner until 8 PM, so 30 miles up the road I stopped at a BP/McDonald’s, topped off the fuel tank, and had some French fries. The stop added 30 minutes to my ETA but it took the edge off of my hunger which made for a more comfortable drive.

On the drive home I suddenly had the vague feeling that I had not turned off the 12VDC fresh water pump in the bus. I called Butch and had him check it. As I suspected, it was on so he switched it off. The only reason this was a concern was that a leak downstream of the pump would result in the (full) fresh water tank eventually being pumped dry (lots of water flowing somewhere) and the pump then continuing to run until it burned out or burned up (fire?).

A little farther down the road it occurred to me that leaving the Aqua-Hot turned on tomorrow, while Butch and Fonda were gone for most of the day, was probably also not the best idea I’ve had recently. I stopped at the Travel America on M-60 at I-69 and called Butch again to ask him to turn the Aqua-Hot off in the morning right before they left.

On the drive home fall was definitely in the air and perhaps even an early touch of winter. I drove through heavy, blinding rain with strong cross winds just northeast of Elkhart, Indiana and was in and out of rainy/windy conditions for most of the drive in Michigan. I called Linda as I passed Charlotte, Michigan which was less than an hour from the house. I got home at 8:10 PM and she had dinner waiting which was nice. We had a green salad and an Amy’s Roasted Vegetable pizza. After dinner I unloaded everything from the car except the few tools I had brought back with me, and the defective Aqua-Hot. We were both tired after long days and turned in early.

2014/10/04 (S) Chores

It continued to rain overnight and into this morning and we awoke to temperatures in the upper 30’s (F). We went to our ham radio club breakfast and lingered until 10:15; longer than usual. When we left we headed to Country Squire in downtown Howell to pick up the hose and cover for the Broil King outdoor grill. We stopped at the bank and then at Teeko’s for three pounds of fresh roasted coffee beans. Our last stop was Meijer’s, just across the street from Teeko’s, to stock up on non-perishable food for me for the next week. While we were there I got a phone call from Chuck and agreed to meet him at his bus garage at 1 PM. By this time it was already 11:30 AM. We unloaded groceries at home and had a quick lunch of hummus, chips, and grapes. I left at 12:30 PM and Linda settled in for the afternoon to work on her bakery project.

Chuck had re-installed his repaired tachometer and installed his new VDO speedometer and I wanted to see how the speedometer/odometer was wired and get the model number. It was a VDO-437-152 85mm 85/130 (MPH/KPH). Chuck had also purchased a dual multistage battery maintenance charger and we had a long chat about where to install it and how to wire it in. While I was there Linda sent a text message asking me to pick up rolled oats so she could make another batch of granola.

I stopped at the Meijer’s in Wixom, topped off my fuel tank, and bought three bags of Bob’s Red Mill Thick Rolled Oats and two bottles of wine. Back home I started doing the laundry and working on my computer off-loading photos from my camera. Linda wrapped up her work and took a break to read before starting dinner. I backed the car up to the garage and we unloaded the spare Aqua-Hot onto a wheeled platform. The unit was very heavy, but we got it out and down safely.

For dinner, Linda made a nice green salad, cooked up a really yummy squash we had not tried before, and made seitan stroganoff served over basmati rice. After dinner she read and played online word games with her friends and relatives while I edited blog posts at my computer. I brought the laundry up and Linda helped get my clothes packed for tomorrow. Butch called to let me know that they were back from their family reunion and the Aqua-hot started right up when he turned it on. Cool (hot).

2014/10/05 (N) Indiana Bound

Linda helped me get partially packed yesterday and I stayed up later last night than I should have, so I slept in a little bit this morning, but the smell of coffee brewing and breakfast cooking got me out of bed. Linda made a tofu scramble with onions, mushrooms, and green peppers and served it with toast and coffee. That was a nice way to start the day.

After breakfast I checked e-mail and then started gathering up the remaining items I needed to take with me to Indiana. I had more clothes than the last trip since I would be gone seven nights rather than three and I would be involved in working on buses initially and then attending a rally. This time of year the clothing needed to work outdoors can also vary considerably from day to day and even during the course of a day.

By 11:30 AM I was ready to load everything into the car. Bags of food went on the floor in front of the passenger seat, my computer and carry bag went on the passenger seat, and the suitcases and bag of shoes and coats went behind the front seats. I then backed the car up to the garage and loaded the items we hoped to get rid of at the FMCA Great Lakes Converted Coaches (GLCC) Surplus and Salvage Rally later in the week.

With the car packed, Linda reheated the seitan stroganoff from last night for lunch. Even left over it was delicious. By the time we finished eating and cleaning up it was 1:15 PM. There wasn’t anything left to do at home, and Linda was waiting for me to leave before she got to work on the bakery software conversion project, so a farewell-until-later kiss sent me on my way. I pulled out of the driveway at 1:24 PM.

The weather looked and felt more like early winter than early fall with moderately strong coldish winds moving an endless layer of mottled gray clouds from west to east. It was neither gloomy nor foreboding but had that wintery edge to it. I thought about alternate routes out of town but decided to take Hacker Road to M-59 the same way I do in the bus. Most of my route was the usual; M-59 west to I-96 west to I-69 south to M-60 where I stopped at a McDonalds to rest and get a cup of coffee. I then took M-60 west through Three Rivers to M-40 where I made a rest stop and topped off the gas tank at the Shell station. Regular was $3.19, a price I have not seen in quite some time. I took M-40 south seven miles to US-12 and headed west to M-217 (the Michiana Parkway) which runs south into Indiana where it becomes CR-17. Instead of continuing on to US-20, however, I took CR-4 west to Elkhart Campground.

I stopped at the campground to make a reservation for Wednesday through Sunday (for the rally) but found out that I did not need one. I confirmed the availability of 50A electrical service while I was there, took the opportunity for a pit stop, texted a trip update to Linda, and then continued my trip to Twelve Mile, Indiana. Since I was in Elkhart and had a good phone signal I called Michele Henry of Phoenix Paint to remind her that I would be in Elkhart later in the week and that we had talked about getting together to review and finalize an article I had written some time ago on the process of renovating the exterior of our coach.

I took SR-19 south through Elkhart to US-20 west to US-31 south. The conversation with Michele lasted about three quarters of the way to Twelve Mile where I finally reached an area with no Verizon cell phone service. (I find it odd that there is any stretch of US-31 without Verizon service as it is the major connection between Indianapolis and South Bend.) I exited at Rochester onto SR-25 south and took that as far as Fulton where I took a couple of small county (farm) roads down to SR-16 at a point slightly west of Twelve Mile and drove east into town. The trip took almost five hours, including the two stops, and covered 245.7 miles.

I had a marginal cell phone signal so I sent a text message to Linda letting her know I had arrived and asked her to call my hosts’ phone around 7:30 PM. I said “Hi” to Butch and Fonda and then excused myself while I unloaded the car. I unpacked the suitcase and stored most of the clothing in the bus, taking enough items into the house for the next couple of days. I also unpacked and stored all of the food in the bus pantry. I put my technology, toiletries, shoes, and work jackets in the house and then went back to the coach to have a quick bite of dinner.

I made my final trip for the night from the coach to the house just before 7:30 PM but managed to be in the house when Linda called. She chatted briefly with Butch about some business related forms and then chatted briefly with me. She will be working at the bakery most of the week, but plans to drive to Elkhart on Friday morning to visit with GLCC chapter members, have dinner, and participate in the business meeting. She’s the chapter Treasurer. She will stay the night, and through breakfast and lunch on Saturday and then head back to the house. We can only leave the cats alone for so long.

Butch was working at his computer but cleared a chair off for me. He had his 2m ham rig dialed in to the Miami County Amateur Radio Club repeater and they started their weekly net at 8 PM. We had a long chat before I retired for the evening around 9:45 PM.

The plan for tomorrow is to continue working on the kitchen and ceiling light wiring in their bus. I also have a few more places to look for the diagrams and installation notes for the Zena 24 VDC engine-driven power generating system. Butch has an appointment on Tuesday morning and will pick up some things while he is in town. I need a fuel line coupler (double barbed male) so I can remove the fuel lines from the final/secondary fuel filter on my Aqua-Hot, connect them together, and see if that eliminates the air bubbles. He also needs parts for the rigid links he is making for the leveling valves for the bus chassis air-suspension system. He is going to get extra material and make a set for me too. It should be an interesting and varied week.

2014/10/06 (M) No Fuel Flow

Getting our Aqua-Hot to work is proving to be quite a challenge. When Butch and Fonda got home early Saturday evening Butch turned on the burner and it fired up perfectly within the normal startup cycle time limits. He left it on and I assumed it was working correctly when I arrived yesterday. It wasn’t until this morning that I realized I did not have hot water. The switch was on but when I checked the expansion reservoir it was below the minimum cold level. The unit had obviously cycled off and then failed to restart sometime later. Once that happened the control circuitry locked out the fuel and ignition spark as a safety measure. I tried cycling it four times but it would not ignite.

Butch found a small inline (secondary) fuel filter and I replaced the one in the unit. It still would not start. I disconnected the fuel line from the outlet of the Racor fuel filter (which feeds to Parker FPM-50), disconnected the fuel line from the outlet of the FPM-50 (which supplies the burner), and connected the supply line directly to the Racor filter. It still would not start. Based on what we could see in the transparent secondary fuel filter the unit was not getting fuel. There are a limited number of things that could be wrong: no fuel; bad fuel; clogged/restricted fuel line(s); clogged/restricted fuel filters; weak/broken fuel pump; stuck fuel valve or defective fuel valve solenoid; clogged nozzle. We started the generator, which may use the same main tank pickup tube as the Aqua-Hot, and it ran beautifully. I turned the electric toe-kick heaters on to put some load on the genset and let it run for a while.

Our next step was to change the Racor fuel filter / water separator and/or by-pass it, but it started to rain. The forecast was for rain throughout the morning turning to thunderstorms in the afternoon with temperatures in the upper 50’s. I did not want to work in those conditions so I put away my tools, closed up the coach, and spent the rest of the day (except for a quick lunch break) working on the 120 VAC wiring in Butch and Fonda’s coach. I hope we have power to their new switched kitchen outlets and ceiling mounted fluorescent lights by the end of the day tomorrow.

I had leftover Ghallaba for dinner. It was delicious.

Butch ordered a VDO-437-152 electronic speedometer/odometer for me from PartDeal.com which is part of ISS Pro (Instrument Sales and Service) with overnight shipping. He then called Joe and got the address of the place in Quartzite, Arizona where we are thinking about spending part of the winter. He and I spent some time checking it out on Google Maps, Google Earth, and Google Street View before turning in for the night. I spent some more time checking out Quartzite and distances to the nearest towns with decent shopping. I dealt with several e-mails, worked on yesterday’s blog post, and finally turned out the lights.

2014/10/07 (T) Loose Connectors

I was up much too late last night and stayed in bed this morning until just after 8 AM to make sure I got my 7 hours of beauty rest. I was up and dressed by 8:40 AM, just in time to converse briefly with Butch before he took off for a shopping run and an appointment in Logansport. Our plan was to attack the Aqua-Hot fuel flow problem when he got back, weather permitting.

After Butch left for town I had my usual bowl of yummy homemade granola for breakfast. Rather than make coffee, however, I went across the street to the Small Town Brew coffee & bake shop that Lisa Paul opened a little over two years ago. Lisa wasn’t there, but her friend Ashley was covering for her. Coffee is on a donation basis and the only small bill I had was a $1, so I got a large mug of coffee, with a refill, for a buck. Ashley was engaged in a conversation with a local farmer when I arrived. She was very friendly, and included me as much as she could, but they were discussing local issues (of course) which involved family relationships and property sales, none of which meant anything to me.

I found out that Ashley’s boyfriend, Jeff, is slowly trying to buy up the whole town of Twelve Mile and turn it into a rental community. Ashley helps Jeff renovate each property to make it rentable. What they are doing probably makes some economic sense but long-term will destroy any sense of community that may exist in this place. Renters simply do not have the same stake in a community as owners. The town is very small with very little employment but is only 12 miles from three much larger towns (Logansport, Peru, and Rochester) and only 30 miles from Plymouth (north) and Kokomo (south), so it is possible to live here and drive to employment elsewhere.

Although Twelve Mile has a bank and a post office it seems like the sort of place younger and middle aged folks might rent for a while rather than someplace to settle for the long term. I am, of course, looking at this through the eyes of a lifelong urbanite. Butch and Fonda have lived here for a very long time and it has certainly met their needs for a place to live and run their business, as well as build/store their bus conversions.

I finished my coffee and returned to our bus to see if I could remove the defective speedometer. The dashboard cover just lifts off, providing access to everything on the back side. Not good access, as the dashboard is fairly close to the windshield, but access nonetheless. I can also see the back side of the dashboard clearly through the windshield, so a second person can help direct tools into position if needed.

The old speedometer is held in with a U-shaped bracket secured with two Nylok nuts on machine screws that are part of the case. The machine screws protruded far enough beyond the nuts to require a deep socket or a socket with a large enough through hole to allow the screws to pass through. In order to get the socket onto the nuts I had to hold wiring cables out of the way. I traced the wires coming out the back of the speedometer and discovered that the instrument connector was disconnected from the mating piece in the wiring harness. The connector for the instrument lights was also unplugged. Whatever the condition of the instrument it was guaranteed not to work in this configuration.

I do not recall how this situation came to be. I was working on the dashboard wiring this past March while we were in Williston and presumably cleaned these contacts as the intermittent speedometer was the primary thing we were trying to fix. Presumably I either failed to plug these connectors back together or did not plug them together fully and they eventually worked loose. Having the connectors touching loosely could certainly have caused the intermittent and erratic readings I was seeing. I decided to leave the speedometer in the dash, reconnect it, and see what it did on the drive to Elkhart. I will have to decide whether to install the new speedometer when it arrives or keep it as a spare. Either way I will need to test drive the bus. Whatever I decide I do not plan to return the new one since it is the correct replacement part (per Prevost) for a speedometer that may eventually fail if it hasn’t already.

While Butch was away I worked at my computer selecting and editing photos for a few of the late September blog entries that I have not yet posted. I should have some free time at the upcoming FMCA GLCC Surplus and Salvage Rally to get the blog and website caught up and also get some writing/editing done on articles for Bus Conversion Magazine.

With regards to my Aqua-Hot, Butch’s plan was to install short fuel lines on the inlet and outlet sides of my Racor fuel filter / water separator, insert T-fittings, reconnect the normal fuel lines to the T-fittings, and attach vacuum gauges to the T-fittings. This configuration would allow us to monitor the relative pressure in the fuel lines on either side of the Racor to see if there was a restriction. I have a replacement filter cartridge for the Racor but we did not want to install it unnecessarily. It would have been easier but provided us with less information.

Although there are several components inside the Aqua-Hot that could restrict or prevent fuel flow, all of those came from Butch’s unit and were known good components before we swapped them over. We also had the unit in our coach operating as recently as this past Saturday. At this point all indications are that the no-start problem is fuel supply related and external to the unit, i.e., in our coach. Ugh.

My new VDO speedometer arrived while Butch was gone. I could not find Fonda so I signed for it. I was eating lunch when Butch got back. He bought barbed brass couplings for 1/4″ fuel line and 11′ of fuel line. He did not buy T-fittings because he had a quantity on hand. Unfortunately we could not find them so I made a quick run to Logansport to get the missing pieces.

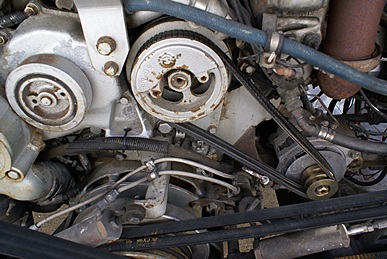

Pressure gauges and T-fittings for testing the Aqua-Hot fuel delivery.

When I got back I hookup up the two vacuum gauges as previously described and initiated a start cycle on the Aqua-Hot. We did not see an indication of a restriction but the unit still would not fire. On two prior occasions we had gotten it to ignite by using a jumper wire across the two terminals where the cockpit switch wires connect. We tried that again and it lit up. It was producing a lot of black exhaust so I let it run long enough to clear up.

The jumper wire may be a coincidence but I developed a hypothesis that we could test. If the initial switch closure provided a sufficient voltage and current to start the operating cycle but then dropped below some lower threshold the controller would never open the fuel valve or apply power to the ignition coil for spark and the blower would complete the shutdown purge stage of the operating cycle. I recall a quote from Thomas Huxley: “The great tragedy of science – the slaying of a beautiful hypothesis by an ugly fact.” With the cockpit switch closed (on) Butch measured 12.7 VDC across the terminals without any noticeable drop. Even so, we investigated the switch and it’s wiring to see if the contacts might be intermittent. They were not. We did discover that the small “grain of wheat” light bulb in the switch was not coming on even though the filament appeared to be intact and there was voltage on the wire pair from the Aqua-Hot that powers it.

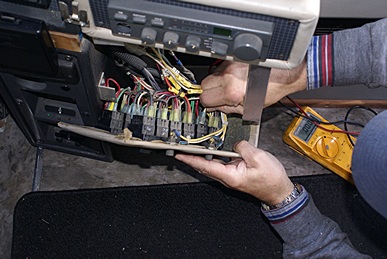

One of the house systems switch panels. The Aqua-Hot burner switch is one of these.

We cycled the unit on and off several times and it ignited every time. I removed the vacuum gauges and T-fittings, spliced the supply hose back together on the inlet of the Racor fuel filter /water separator, reconnected the outlet to the inlet of the Parker FPM-50, and installed a new piece of 1/4″ fuel line from the outlet of the FPM-50 to the inlet of the secondary fuel filter. I checked all of the band clamps, turned the unit on, and it started right up.

I did a little more interior electrical work on Butch and Fonda’s coach, helped them install an FRP panel, and called it a day. Since I was leaving tomorrow I did some preliminary packing of stuff in the bedroom. I made and ate my dinner in the coach and then did some straightening up before returning to the house and turning in for the night.