To paraphrase, “If it’s Saturday we must be in South Lyon” and that was, indeed, the case. Most of the regulars were missing from our weekly breakfast gathering of the South Lyon Area Amateur Radio Club (SLAARC), but six of us showed up and had a great conversation. By the time we headed towards home it was starting to rain lightly.

We stopped at Brighton Honda to get some information on the Honda Ridgeline pickup truck. The salesman was very nice, but unfortunately Honda has stopped making the Ridgeline. They are reintroducing it in the fall of 2016, but we will likely make a decision about a new car/truck sooner than that. There are still a few in stock around the country but we already have an orphaned Honda Element. We like the car, but would be happier if they were still being made. In this case, however, it was a moot point as the Ridgeline is not towable four wheels down.

We drove next door to Brighton Ford to look at F-150 pickup trucks. We were assisted by Frank Stapleton and he was easy to work with. He insisted that we meet his new car sales manager, Eric Wilkinson, before we left. We felt that was unnecessary at this stage in the process, but he also seemed like a nice enough guy. The entry level XL 2-door may be reasonably priced (not really, but what car is?), but the slightly nicer XLT 4-door short bed with 4-wheel drive, towing package, and off-road package looks like it would price out at $45,000 give or take three grand. Without X -Plan pricing that is simply not going to happen, and even with X-Plan pricing it is not a sure thing. Frank really wanted us to test drive one but given the rainy weather we were not in the humor to do that today.

The F-150 is a nice truck, nicer in fact than many cars, and perhaps nicer than a pickup truck needs to be or should be. On the plus side it certainly has ground clearance, but on the negative side (for us) it is also BIG. The back seat room in the four door body style is cavernous, made larger by fold up seats, and that would be very useful for us when traveling in the bus. Between the back seat and the bed we could store a LOT of stuff. It has well-placed handles by all four doors, and it is a god thing as we both needed them, along with the running boards, to get in and out. There are several engine options including the 2.7 L and 3.5 L Eco-Boost models, both of which feature twin turbochargers. These are high-tech engines, with incredible power and torque and decent fuel economy. I liked the sound of that, but unfortunately that technology comes at a significant price premium. Interestingly, Ford is using an aluminum body and the truck weighs in at about 4,700 pounds. Our Honda Element weighs over 4,000 pounds and it is not nearly as big as the F-150. How well the aluminum will hold up is unknown.

We were almost home when we decided to keep driving and visit LaFontaine Nissan. While not as convenient as the Brighton dealerships, it is only 15 miles from our house, 13 of those headed east on M-59. Linda checked their hours on her phone and they were open until 4 PM. The purpose of our visit was to look at the Nissan Frontier pickup truck and the Nissan Xterra SUV, both of which Edmonds.com suggested were viable off-road alternatives to a Jeep Wrangler while Consumer Reports indicated they were more reliable and more practical than a Jeep Wrangler. Bobby Lundwall, the Commercial Manager, assisted us and we met the General Sales Manager, Don Poley, before we left. Bobby was very helpful and brought a Frontier and Xterra around front for us to see. Again, we were not interested in test driving one at this stage, especially in the rain.

The Nissan Frontier pickup has an available 4-door, 4-wheel drive, short bed model. It is considered a mid-size truck and is noticeably smaller than a Ford F-150 in every way. The Pro-4X off-road version has 10.1 inches of ground clearance at the differential, which should be adequate for our needs. It has a transfer case but is only towable four wheels down with the 6-speed manual transmission. We looked at the Xterra but found it harder to get in and out of, especially the back seat. It is taller than the Frontier and after due consideration we agreed that we were not really in the market for an SUV.

The Frontier does not have the bewildering array of options that the F-150 has and would be more suitable for the 95% of our driving that is on local paved and dirt roads. It would be perfectly adequate for hauling materials from Lowe’s to the house and has an available tent option for camping. We presume that aftermarket bed covers, canopies, and even small truck campers are available but we would check on that before buying one. Ditto for Blue Ox base plates and the ability to install an SMI Air Force One auxiliary braking system.

We did not test drive one, but it was easy to get in and out of, and comfortable to sit in, at least in the front seats. It weighs about 4,500 pounds, basically that same as the much larger F-150. The only negatives at this point are the manual transmission and lack of choice on interior fabric; the Pro-4X only comes with a charcoal interior, either cloth or leather. The bottom line was that it is probably a better fit for us than a Jeep Wrangler or a Ford F-150 and could be acquired for under $35,000 equipped the way we want it. Nissan also has zero percent financing available at the monument, although that is often in place of other incentives. The fact that it requires a manual transmission to be towed four wheels down, however, probably knocks it out of contention.

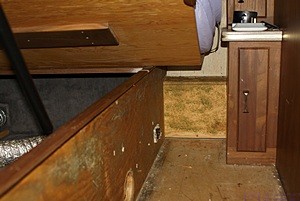

Storage compartment under the lift-up bed platform. The two boxes concealed and protectd 4″ flexible HVAC ducts.

Once we got home we had a light lunch. I then changed into my work clothes and got back to work deconstructing the inside of our motorcoach. (I like the term deconstructing as I think it is more descriptive of what I am doing that demolishing or even disassembling.) My goal for today was to finish removing all of the carpet and all of the carpet tack strips. I accomplished all of that except for a piece of carpet on the wall behind the driver’s seat and a piece on the front wall of the entry stairwell. My first task, however, was to cut a short slot in the 3/8″ plywood filler that was under the dinette in order to free an AC electrical cable that ran through it and then through the floor.

Getting the carpet off of the sides of the bed platform was interesting. There was a piece of wood trim installed along the top edge of the side of the bed base facing the front of the bus and just under the plywood bed platform. The trim strip is rabbited on the underside and conceals a 12VDC strip light that is tied in with toekick lights in the bathroom and the floor lights in the hallway. The power for the lights comes from inside the bed base through a small hole in the plywood and carpet. The trim strip also appeared to be installed over the carpet and needed to be removed to get the carpet loose along the top.

There was also an adjustable HVAC louver on each side of the bed. The louvers were installed from the outside and had flexible heater ducts slipped over them on the inside and secured with screws. The flexible ducts were in the storage area under the bed and were covered by wood boxes to protect them. The boxes, in turn, were carpeted to match the rest of the storage compartment. To disconnect the wiring for the strip light and remove the boxes I had to first empty out all of the stuff stored under the bed so I could get in there to work. The bed platform is hinged about one foot from the head end and the foot end lifts up, supported by two gas struts, so there was plenty of room to work once I emptied it out.

I have disassembled enough of the bus at this point to have some idea of how the conversion was built. The cover “boxes” for the flexible ducts were actually half-boxes with a long side and top and one small end. They were installed into a corner using a cleat screwed to the floor that the bottom edge of the long side was then screwed into. There was a similar arrangement to catch the free edge of the top and it was screwed to the inside wall of the platform base. All of these screws were put in through the carpet that covered the boxes and were essentially invisible so I had to find the screw heads by touch and back them out.

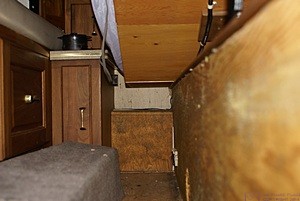

The area just forward of the bed base with the bed platform raised and facing the driver side of the bus.

Once I got the protective boxes loose I discovered that the floor and wall were also carpeted. There was a small bump out in each rear corner that served as wiring chases for AC electrical outlets on each side of the bed, and these bump outs were carpeted. It seemed clear to me that the HVAC ducts, which are part of the OTR HVAC system, may have originally been installed directly into the HVAC chase outside the bed base and later repositioned to the sides of the bed thus requiring the louvers, flexible ducts, and cover boxes. They also greatly reduced the available storage space under the bed.

The OTR HVAC chase runs along the floor-wall junctions on both sides of the bus for most of the length of the coach and a 12″ section of it is accessible on either side of the bed. Removing the two flexible ducts, sealing up the openings, and installing the louvers outside the bed platform will free up additional storage space under the bed which is a good thing as we can always use for storage space. That’s a nice bonus but adds some additional work to the remodeling project. Such is the nature of remodeling; you never really know what you have until you have completed the deconstruction phase.

The aft side of the bed base. There is not a lot of room to work in here so I will remove the bed platform when I install the new tile floor. I plan to use the same tile on the sides of the bed base.

It was overcast all day with humidity near 100% and rained off and on into the evening. It was also warm so I kept opening the roof vents and running the fans to make it more comfortable in the coach, but every time I did it started raining shortly thereafter. When I was done working on the bus for the day I moved the ten concrete blocks that had been supporting the propane tank for the whole house generator and pulled up the utility marker flags for the underground gas line to our meter. Keith will be here to cut the grass this coming week and I want him to be able mow these areas.

Linda spent the afternoon thoroughly cleaning the kitchen. She also prepared a sugar-water solution, filled the hummingbird feeder we bought at Lowe’s the other day, and hung it off the railing of our rear deck. A hummingbird found it almost immediately which was very cool. For dinner Linda made pan-grilled tofu slices with caramelized onions and sweet BBQ sauce served on tortillas. She also sautéed fresh broccoli and sliced up some fresh strawberries and pineapple.

After dinner Linda went to the Edmonds.com website to see if she could get a better feel for dealer cost and Fair Market Value for the Ford F-150 and Nissan Frontier. While she was at it she looked up the Chevy Colorado (GMC Canyon), and Toyota Tacoma. The Chevy Colorado was Motor Trend Magazine’s 2015 Truck of the Year. Both the Colorad0/Canyon and Tacoma are mid-sized pickup trucks. Toyota’s full-size pickup is the Tundra.

Brendan called while we out to see if Linda could sit with Madeline tomorrow night while he and Shawna had dinner with their friend Jorge. Depending how the day goes tomorrow I may go to Ann Arbor with her. We had two episodes of Sherlock left to watch and the DVDs have to go back to the library on Monday, so we watched both of them this evening. It was a double feature so I made popcorn in-between episodes.