[Note: There are no photos for this post compilation.]

2016/04/26 (T) Amazing Amazon

We had lightning and thunder last night starting around 9 PM but the rain held off until bedtime. When it did start it was not heavy and did not last for long, or we were asleep and unaware of it. The Lightning was intense for a while but the storms must have been a good distance to our north as the thunder was never very loud. By morning the cold front had moved well east of us and left thick fog in its wake. We were both finally ready to get up at 8:45 AM, which is a bit later than usual. I made a smaller pot of coffee while Linda showered and got dressed. We usually enjoy our first cup of coffee before having breakfast but she toasted bagels for our breakfast right away. She had an 11 AM dental appointment in Dearborn and needed to be on the road by 9:30 due to road construction projects on I-96 and I-275.

I spent the morning working at my computer. I updated my address book, sent an e-mail to some old friends in Ann Arbor (Mitch and Barb Goodkin), and wrote a draft of a letter to our old friend, Wayne Hopkins, who lives in Maryland just north of Washington D.C. Wayne does not use a computer so he does not do e-mail, which means we have to use vintage methods to communicate with him. I used to write a lot of letters, and in some ways I miss it.

Linda got back from her dental appointment much later than I expected. I thought she was having a crown installed but she was actually getting the tooth prepped and was in the chair for over two hours. She goes back on May 18 to get the crown.

We had vegan hotdogs for lunch. After lunch Linda made a southwestern bean soup in the Instant Pot and then spent a couple of hours studying the question pool for the Amateur Extra Class (ham radio) license exam.

I returned to my desk to research color laser printers. I came to the conclusion that we need to move the HP LaserJet 3600 back to my office and get a smaller/lighter printer with built-in wireless networking capabilities to use in the bus. Smaller/lighter is always good in the bus and the wireless feature will remove constraints on where the other networking technology can be located relative to the printer.

I also researched print server/adapters for connecting our HP LaserJet 4200 to our Ethernet network. The 4200 is a fabulous, 1200 dpi, 28 page per minute, monochrome laser printer but it is old enough that it only has a Centronics parallel printer port. I have had it connected to our network for years through an old LinkSys SCBX3 3-port print-server that is (apparently) too old to work with computers running Windows 10. Or perhaps it just finally failed. Whichever, it no longer works. I found a device on Amazon, made by StarTech, which claimed to do what I need so I ordered one. It remains to be seen if I can find Windows 10 compatible drivers for this printer, but I think it uses PCL6 (like many HP printers) so I am optimistic about my chances. While it is amazing what can be bought through Amazon, and how easy it is to buy it, I also find it discouraging how much time it can take to find and purchase even simple things. And it has certainly been the case that I cannot always find what I am looking for.

I had an exchange of text messages with Chuck Spera about axle seals and brake parts for our Prevost tag axles while Linda prepared dinner. She started with a nice salad of mixed greens and included dried cranberries and walnuts on mine but left them off hers as she has to avoid chewy, sticky, and crunchy things until she gets her permanent crown.

Purple Heart called to let us know they are going to be on our street on Wednesday next week and wanted to see if we might have anything to donate. Linda figured it was a good opportunity to get rid of most of my suits and sports coats and I reluctantly agreed. Not that we need the closet space they occupy for something else, but even I recognize that at some point I need to divest myself of things I no longer use and probably never will again. That prompted her to pull several countertop appliances out of storage for possible donation.

The old Kitchen Aid mixer no longer works but is mostly made of metal so we think it is recyclable. The four-cup coffee maker I had in my office for years works fine but is no longer needed so it will get donated. She also pulled out a tea maker we haven’t used in years but we decided to see if it was still functional by making a pot of tea. It worked, so we will probably keep it, at least for now. Hey, two out of three is pretty good for us (me).

NCIS and NCISNOLA were both repeats but Limitless was a new episode and also the season finale. It was a good one, with a good setup for next season. We watched the weather and then headed to bed where Linda read for few minutes while I watched some more TV and worked on this post before going to sleep.

2016/04/27 (W) A New Mixer

I went to bed last night knowing that I had to get up early this morning and move the trash can to the street. Even without setting an alarm I was suddenly awake just after 7 AM. I put on my sweats, gathered up some last minute trash, put it in the container, and rolled it to the end of the concrete driveway. The morning air was very brisk, the sun was low but very bright, and the grass, which looked like it had grown six inches as a result of the recent rain, was covered in dew. It was a lovely spring morning in the country. I took the mailbox key and retrieved yesterday’s mail.

I started to prepare our morning coffee but took a few minutes to first clean the coffee maker. I then ground up six scoops of Ethiopian Yirgacheffe beans (half caffe) and brewed seven cups of coffee. Linda was up by the time it was ready and we enjoyed our first cup in the living room with Juniper (the cat) on my lap and Jasper (the other cat) next to Linda.

Linda arranged to meet Diane at Kensington Metropark this morning to restart their weekly walks. We were expecting delivery of the new Kitchen Aid mixer today, so I was confined to quarters while she was away. That was fine; I like being here, and I have plenty of computer/Internet based work to keep me occupied.

I wanted to upgrade the WordPress version and plugins on the four websites I manage but decided I should do backups first. All four sites are incrementally backed up automatically every week using the WordPress Backup to Dropbox (WPB2D) plugin but I wanted to do complete backups before initiating these particular upgrades. I have never done a complete manual backup so I started reading about how to do it and quickly realized that it was more complicated than I wanted to deal with at that very moment. The cPanel has backup features so I tried to explore using those but their use wasn’t any clearer. I finally e-mailed support@qth.com for advice/assistance.

I also needed to upgrade the hosting plan for the SLAARC account so I logged in to try and do that. This is not something I do very often so I stumbled around until I finally found what I thought was the right place to be, but again it wasn’t clear exactly what to do. I logged out and e-mailed sales@qth.com for assistance.

I spent more time researching color laser printers on BestBuy.com and found a Samsung SL-C1820W that looked like it would meet our needs in the bus. It’s smaller and lighter than the HP Color LaserJet 3600 but still prints 19 pages per minute at good resolution. Of equal importance, however, were the several different built in wireless networking capabilities along with a USB 2.0 interface and a wired Ethernet network port.

One of the other things I have been researching is a replacement for the three Fan-tastic Vent Fans in the bus. I have pretty much settled on the Airxcel MaxxFan Deluxe 7000K (white dome). I will probably order one initially to replace the one in the bedroom and see how the installation goes. If it goes smoothly, and I like the fan the fan works, I will probably order two more, one for the bathroom and one for the kitchen.

Late yesterday I got the Word doc version of the latest CCO newsletter from Ed Roelle with a request to convert it to PDF. I did that and sent it back with a suggestion that he pick up the info on Donn Barnes’ Bluebird from the recent GLCC Newsletter.

Linda stopped at the Meijer’s supermarket in Brighton on the way home from her walk. When she got home we had vegan hotdogs for lunch and split a very nice pear. Recycle Livingston is open on Wednesday afternoons and Saturday mornings so Linda gathered up our recyclables and drove them over. By the time she returned UPS had delivered her new Kitchen Aid mixer so I helped get it out of the (three) boxes in which it was packed and set in on the kitchen counter. Apparently Alchin’s had also picked up our trash so Linda rolled the empty container back to the garage.

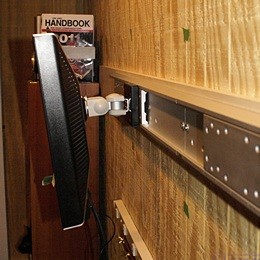

I had a reply from AJ at WiFiRanger (BlueMesh Networks) so I tried once again to get our WiFiRanger Mobile Ti to work. I was able to connect my iPad2 to the WFR, and I was also able to connect the WFR to a couple of different external Wi-Fi (WAN) signals and establish a connection to the Internet, but neither the LAN or WAN connections would stay connected. AJ provided RMA instructions and as soon as I can get on the roof and remove the WFR-MTi from its mount I will mail it back to see if they can figure out what is wrong and repair it, if possible.

I exchanged several e-mails with Gaye Young and Daniel Ball from FMCA regarding the data from the Education Survey. I then got a call from Curtis Coleman of RVillage with an update on his meeting today with the FMCA Executive Board. He said it went well and he was very upbeat about it and the future of RVillage. As minor investors in the project, that is the sort of news we like to hear.

For dinner, Linda made vegan burgers using the leftover mixture that Meghan gave us on Sunday. She grilled them on our outdoor gas grill and served them open-faced on a bed of lettuce. She also sliced 3/4″ thick cross-sections of cauliflower, applied a complex mix of seasonings, and grilled them. What appeared to be a simple meal was actually a subtle but wonderfully complex culinary experience.

I chatted for a while on the phone with Butch about bringing our bus to their place in the second week of May to work on the brakes of both buses, make some repairs to our water bay, and help with other projects. I then called Mike to see if he knew when Sloan’s might have his lawn tractor ready for pickup. He had just found out that it should be ready to pick up tomorrow or Friday. Linda will be at the bakery all day tomorrow and I have to take the cats to a 2:20 PM appointment at Plaza Veterinary Hospital in Farmington. We also have eye exams on Friday at 10 AM, again in Farmington, so my best window for going with him is Friday afternoon, and I shared that information with him via e-mail. I had an e-mail back from Ed regarding Donn’s e-mail address so I called Donn in Alvarado, Texas to confirm his contact information and catch up on things. I then e-mailed Ed and cc:d Scott Bruner, the GLCC newsletter editor, to give him the updated contact info for Donn.

Wednesday night is PBS nature and science night for us. Nature had a wonderful program on owls which was followed by an equally wonderful episode of Ken Burn’s The National Parks: America’s Best Idea. It was PBS at its best.

2016/04/28 (W) P.V.H.

I got up at 7:30 AM, showered, got dressed, and made a pot of Costa Rican Terrazu coffee, noting that there were widely scattered raindrops on our deck. I checked my e-mail for a reply from Mike relative to going to Sloan’s but did not have one. I did have an e-mail from Ed with a revised CCO newsletter, however, so I converted that to PDF and sent it back to him so he could distribute it to the members without further delay. Linda was showered and dressed by 8 AM and toasted bagels for our breakfast. She wanted to be at the bakery by 10 AM, so she packed up her computer and was out the door 8:45 AM. She wanted to go in later as she arranged to have dinner with Kathi Slater after work and didn’t think she had more than 6 – 7 hours of work to do.

I get tired of spinning my wheels, going around in circles without actually accomplishing anything, so I logged in to Amazon.com and ordered the Airxcel MaxxFan Deluxe 7000K White vent fan and the Samsung Xpress C1810W color laser printer along with a 3-year protection plan. The printer is list priced at $300 but Amazon Prime had it for $150 with free shipping. The protection plan was $10. Farmington Vision Clinic called to confirm our appointments for tomorrow morning and get our vision insurance information. I then played a few iPad games while I finished my coffee.

In my office I connected the old Sony Vaio (Windows XP) workstation to the network switch and then downloaded and installed updates for various things, including MS Office and ES|ET NOD32 Anti-Virus. While that was going on I opened the Prevost CatBase Viewer database and started looking up the wheel hub and brake parts I might need to service/repair the other three Meritor Air Disc Brakes on the bus. As I found the parts on different drawings and parts lists I created my own spreadsheet so I could send it to Butch and have him forward it to ABC Bus Arts in Muncie, Indiana to check availability.

I stopped working at 12:30 PM to have lunch. I heated a can of Amy’s lentil vegetable soup and had some sourdough pretzel nibblers dipped in Sabra Roasted Red Pepper Hummus. It was easy but also very good.

The cats had 2:20 PM appointments with Dr. David Carron at Plaza Veterinary Hospital (P.V.H.) in Farmington. I got them in their carriers at 1:10 PM and left at 1:20 for the 30+ mile drive. Traffic was moderate but flowing and we arrived just before 2 PM. I took the cats in and put each one on the scale (in their carriers): 12.3 pounds for Juniper and 13.6 pounds for Jasper (after subtracting the weights of their respective carriers). Molly took us back to an open exam room ahead of our appointment time and got some of the preliminary information from me. After she left the exam room I opened both carriers. Juniper was out of her carrier immediately but Jasper did not come out of his voluntarily. Juniper explored the entire room before settling in a corner behind a rolling stool. That’s pretty typical of these two cats.

When Dr. Carron came in we discussed Jasper’s health issues and treatments during the late winter. He seemed to focus on the sneezing of blood as potentially troubling and indicated that a C.A.T. scan was the only way to definitively determine if there was a problem in the sinuses, but did not recommend one at this time. He also said that it’s a bad sign if blood initially comes out of only one nostril but then starts to come out of both at a later time. Jasper’s wellness exam was otherwise normal, as was his full blood analysis, and Dr. Carron did not recommend any other procedures at this time.

Juniper’s checkup was also good except that she has some minor gum irritation and needs to have her teeth cleaned. She needs a Wednesday morning appointment, which I did not make as I might be out of town and Linda would have to handle it. Juniper got her rabies booster shot but we deferred blood work until the teeth cleaning appointment. I paid the bill and was out the door at 3:15 PM.

Traffic was much heavier on the way home and the rain, while light, was now persistent. On westbound I-96 just before Beck Road there was a loud bang on my roof. I immediately assumed my Diamond SG7900 antenna had come loose but I did not see it in my mirrors so I presumed it was still on top of the car. I exited at Wixom Road, headed north, and then pulled into the Menard’s parking lot to see what was going on. Going around the last turn I heard another noise. The antenna was not on top of my car and I was about to walk back towards Wixom Road to look for it when someone pulled up in their car and handed it to me. Apparently it dislodged from the roof on the last turn into the parking lot and he saw fall off.

The SG7900 is a $100 antenna, so I was glad to have it back. It also appeared to be undamaged so I screwed it back into the four magnet Motorola mount. But mostly I was just glad it had not fallen off the car on the highway and caused damage to a vehicle behind me or triggered an accident from someone trying to avoid it. My concern now is that the threads on the mount and/or antenna may be worn to the point that it will not screw on tight enough to stay. Unless/until I replace one/both I obviously need to secure the antenna with some safety lines, such as monofilament fishing line. That would also reduce substantially the flexing forces at the base threads, which may be at least partly responsible for the fitting working loose (which it has done before). This antenna used to be so tight that I carry an offset slip pliers in the car in case I need to remove it. I recently added a small amount of anti-seize compound to the threads, so it is also possible that the compound reduced the friction enough for it to wiggle lose from bouncing and flexing.

I was still home by 4:15 PM and got the cats inside and out of their carriers. In the course of the day I discovered that both carriers have broken fittings and need to be replaced. Linda called at 4:30 PM to let me know she was leaving the bakery and headed to Kathi’s and then to dinner. I washed some grapes and then turned on the fireplace and settled on the couch to doodle on my iPad. I had a notification from Amazon that the StarTech Ethernet to Centronics parallel print-server/adapter had been delivered. I checked and it wasn’t on the front porch. Since it was a USPS delivery I thought it might be in the mailbox. It was, although I was surprised that a box that size was able to drop into the secure lower portion of the box. I opened it to check the parts and glanced at the installation instructions. I then set it aside for later and returned to the living room sofa where Juniper curled up on my lap and went to sleep.

By 6 PM I was ready for a bite of dinner, and nothing says bachelor dinner like popcorn! I also had some dried fruit. Linda called at 7 PM to say she was heading home. I worked on installing the print server on our HP LaserJet 4200 while she was in transit. Not surprisingly I could not install the software on my ASUS Windows 10 laptop so I installed it on the Sony Vaio workstation instead and then used it to reconfigure the IP settings to use DHCP. Even with that I was not able to install the printer on the ASUS, or even see it on the network.

Linda got home at 7:40 PM so I set aside trying to access the printer through the Sony workstation. Thursday night is CBS comedy night so we watched The Big Bang Theory, Moms, The Odd Couple, Two Broke Girls, and Rush Hour. Somewhere in there we enjoyed small glasses of Moscato wine.

2016/04/29 (F) Eye Can See Clearly Now

We awoke at 7:30 AM to overcast skies and intermittent light drizzle. We were up by 7:45 and after feeding the cats I made a small pot of coffee. We had appointments at the Farmington Vision Clinic this morning at 10 AM so we gathered up all of our glasses (seven pairs) and left around 9:20 for the 30 mile, 30 minute trip. Like the veterinary clinic visit yesterday, the vision clinic is only a little over a mile from our old house, but is now quite a drive for us. We have seen Dr. McGrath for so many years, however, that we have not been inclined to find a new service provider closer to where we now live, especially given that we are only here approximately once every other year.

I had not taken the time to secure the ham radio antenna on my car yet so we took Linda’s car. She drove, so I called Mike to check on the status of our pending trip to Sloan’s in Linden. He expected his lawn tractor to be ready tomorrow but had not heard back from them yet. He was going to be tied up most of today but thought he could go up late this afternoon if they called in time. I said that would work for me if needed.

We were at the vision clinic until noon. Besides thorough checkups, which resulted in clean bills of eye health for both of us, we each ordered a new pair of glasses: reading glasses for me and daily use progressive lenses for Linda. Since we were already in Farmington we headed downtown to Chive restaurant for lunch. Linda had dinner there last night with Kathi Slater and wanted me to try it. We ordered a Jalapeño Burger and a Reuben sandwich, both of which came with seasoned French fries, and split them. I also had a root beer float, a rare treat. Everything was excellent, including our waitress Jennifer; and it was all vegan, naturally.

After lunch we returned home. By the time we got there we were both tired and took naps. I was awakened by a knock at the front door, which is unusual here. The man introduced himself as Larry Jones. He and his wife Sue bought the house just east of ours last fall. They moved in just before we left for the winter so we did not get to meet them at that time. Our mail got delivered to their house today, so someone was obviously substituting for our usual mail carrier, Michelle, and not paying attention to addresses on mailboxes. We had a nice chat with Larry and exchanged phone numbers with him. He and Sue have two children that live in Ypsilanti and a third moving back here from Kansas. Sue is a teacher, and they are recreational boaters, so they tend to be out on the water during the summer.

For dinner, Linda reheated some of the southwestern soup she made the other day and served it with saltine crackers and fruit preserves. I got a call from Mike to let me know his lawn tractor was ready. We decided to go pick it up tomorrow after our ham radio club breakfast. He is going to bring his trailer to our house so we can load our broken lawn tractor on it and take it to Sloan’s.

After dinner I worked for a while at my desk. I had replies from Scott at QTH.com and digested his suggestions relative to backing up my WordPress sites. I managed to connect the Sony Vaio workstation to the HP LaserJet 4200 printer and print a test page but was still not able to connect to the printer from my ASUS (Windows 10) laptop through our network. I shared the printer from the Sony workstation and was subsequently able to find and install drivers that allowed the ASUS to connect to it and print a test page. I then printed a draft of a letter to our friend Wayne and had Linda proofread it. I dealt with an e-mail and then joined Linda in the rec room to watch a PBS program on America’s Top 10 Urban Parks, followed by Episode 5 of Ken Burn’s The National Parks: America’s Best Idea.

2016/04/30 (S) Lawn Tractors

I was up at 6:30 AM, Linda was up by 7, and we were on our way to our weekly ham radio breakfast in South Lyon at 7:20. We took Linda’s car as I have not yet had a chance to secure the ham radio antenna on mine. I took my Kenwood TH-F6 handheld and was able to get into the South Lyon 2m repeater on 5 Watts from inside the car. Not bad.

There were 14 people at breakfast and we had a good chat. I took a few minutes at the end to talk to Larry (K8UT) about how to manually back up the WordPress sites. He said a complete backup could be done in four easy steps: 1) Use the cPanel File Manager to create a compressed zip file; 2) Install FileZilla on my computer (free), 3) FTP the zipped file to my computer; and, 4) Use the cPanel Backup Wizard to export the appropriate databases from the web server to my local computer. Larry always makes things sound easy, so I hope it is as easy as described.

We left the restaurant at 9:15 AM and returned home where we uncovered the lawn tractor and rolled it over to the concrete driveway to await Mike’s arrival with his trailer. The left front tractor tire was low on air so I pressurized the small Porter-Cable pancake air-compressor and refilled the tire. It seemed to hold, so hopefully it is OK.

Mike had to stop at the field day site (Lyon Township Atchison Memorial Park) before going home to get his flatbed trailer. When he arrived at our house at 10:45 AM I had him pull into the middle driveway entrance and swing into the new west driveway extension. That allowed us to roll the lawn tractor onto the trailer and allowed him to pull out going forward without having to back up.

The 21 mile drive to Sloan’s in Linden took about 30 minutes. Jeff waited on us and then we unloaded my Cub Cadet 1024 and loaded Mike’s Cub Cadet 1552. Based on my description Jeff thought it probably needed a crankshaft seal, an oil pan gasket, valve adjustment, and perhaps a new voltage regulator. The cost for diagnosis was $37.50 (1/2 their hourly service labor rate of $75). We were there for about 40 minutes and back at my house by 12:30 PM.

Mike stuck around and helped me figure out how to install the HP LaserJet 4200 monochrome printer as a network printer. After scanning our home network with Advanced IP Scanner from my ASUS laptop computer we queried the AT&T gateway/router. This Netgear device serves as the DHCP server for the network and we were able to determine that the range of addresses it generates are from 192.168.1.64 through 192.168.1.250 with the gateway address at 192.168.1.254. We used the current address of the print server, 192.168.1.247, to access the print server administration interface and changed the IP address to 192.168.1.50 (static). We were then able to install the printer and print a test page.

While we were working, Linda heated some leftover western bean soup and made vegan grilled cheese and tomato sandwiches on whole grain bread. She served them with orange segments on the side and a small bowl of loose grapes. Mike and I then installed the printer on Linda’s Samsung laptop computer. Rain was forecast to move into our area starting around 4 PM, and Mike wanted to mow his lawn before it started, so he took off. Linda left at the same time for Meijer’s to get a few grocery items and I took care of several chores. First up was starting a load of laundry.

We had a trash can stored in the small dump trailer all winter to act as a filler under the tarp. It got removed this morning when we uncovered the lawn tractor and trailer, and was sitting in the front yard, so I moved it into the garage. After folding the tarp and recovering the trailer I checked the mail. All of the mail in our box was for our neighbors, so I called Larry to see if they had gotten our mail again. They were away from the house, but he suggested that I walk down and check their mailbox. I did, and they did not have any mail, so the mail in our box was probably from yesterday.

With the outside chores done I returned to my office and checked e-mail. Scott at QTH had looked at our personal account and discovered a 1.9 GB error log file! He deleted it and let me know that it appeared to be coming from a defective backup plugin. We had this same problem a couple of months ago with the SLAARC.com website so WPB2D (WordPress Backup to Dropbox) had to be the culprit. I logged in to all four WordPress installations and deactivated the plugin. That was a shame, as I have counted on this plugin for a long time to keep these sites backed up without my intervention. I will have to find a different one or just do it manually (ugh). I e-mailed Scott back and thanked him for the ‘heads up’ but indicated that I still wanted to upgrade both accounts to his BEST VALUE PLAN.

While I was logged in to our personal site I deleted 276 spam e-mails and marked two others as SPAM that had somehow slipped past the Akismet filter and were being held for moderation. I also discovered that two of the four sites (personal and GLCC) had automatically updated even though I really wanted to do the backups first.

Linda got home at 2:30 PM and the USPS truck showed up about 15 minutes later. Amazon is committed to Prime customers getting their merchandise in two days regardless of when they order. The USPS currently has the contract for weekend delivery, so anything ordered on Thursday or Friday gets delivered on Saturday or Sunday, respectively, by the Post Office. The carrier had both our MaxxFan Deluxe RV vent/fan and our Samsung C1810W color laser printer. I got them inside but did not open them right away.

For dinner, Linda made a very nice salad and an angel hair pasta dish with mushrooms, onions, garlic, sun-dried tomatoes, and arugula. The arugula was an especially nice touch. After dinner we watched TV, catching another episode of Ken Burn’s The National Parks: America’s Best Idea. Linda read and I wrote for a while afterwards before going to sleep.