Linda was up at 5:45 AM again and off to the bakery at 6:15 but this was the last time until spring 2016. There is still more to do on both the software project and year-end accounting but she will do it remotely. We need the weekend and the first three days of next week to get the motorcoach, the house, and us ready to travel and prepare for our Thanksgiving Day family gathering. Also, unlike the last two winters, Linda does not plan to fly home in late February to take care of year-end accounting and tax work. She will handle all of that from Florida instead, so she has to make sure she has everything she needs with her in the bus when we leave.

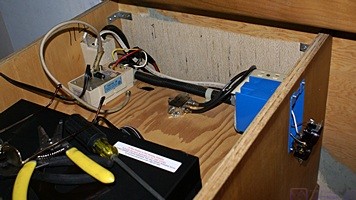

This was likewise the last day for me to work on bus projects. The things I needed to do in the bus included:

- Install metal edging to protect exposed tile edges.

- Grease the steering column.

- Install filter material over the HVAC holes under the bed.

- Mount the West Mountain Radio RigRunner on the dashboard.

- Pull the chassis battery tray out and check/clean/tighten the connections.

But I had a few other things to attend to first.

I was up and dressed at 7:45 and had an alarm set on my iPad for 8 AM to remind me to pick up our coffee bean order from Teeko’s. I had a bowl of granola for breakfast and then called Brighton Honda. My last oil change was at 99,280 miles and I now have over 105,000 on the odometer so I made an appointment for Monday afternoon to have the oil changed. I had a cup of tea in the living room where I spent some time with our cats. I then went to my office and replied to an e-mail from Gary at BCM. I called Teeko’s to make sure our coffee was ready to pick up. Mary did not have it packaged yet but said she would have it ready in an hour. I indicated that it would be longer than that before I got there. I called Discount Tire in Howell to see about having the tires on the Element rotated. They were running 2 – 3 hours so I made an appointment for Monday morning. I called Brighton Ford/NAPA to order an air filter for the bus.

I moved the brass colored stair edging into the bus and checked the temperature. It was 64 degrees F so I bumped the thermostats up just a bit. I also switched the remote temperature sensors so that #1 was in the freezer (top) and #2 was in the fresh food compartment (bottom). I removed the ham radio antenna from its magnetic mount and put it in the car. I finally left at 11:45 AM on my errand run.

My first stop was Wendy’s where I had an order of French fries for lunch. I then went to Lowe’s, which was just across the street, for carpet stain remover and looked at tarps while I was there but did not buy one. I don’t think we will be able to create enough space in the garage for the lawn tractor so I want to cover it for the winter. From there it was less than a mile east on Grand River Avenue to the car wash. I had taken the ham radio antenna off before I left the house but the car wash knocked the magnetic mount cellular booster antenna loose. I pulled into a parking spot, put the cellular antenna back in position, and reattached the ham radio antenna.

I backtracked that same mile and stopped at Teeko’s to pick up our coffee order. It seemed light but Mary already had it bagged and I was anxious to move along so I did not check it. I continued west on GRA to the Bank of America branch near The Home Depot (which I should have done after stopping at Wendy’s). With colder temperatures coming the next few days I decided to drive to the Shell station in Brighton and top off the tank. The sign said regular was $2.059/gallon but the pump I used was set to $1.959. Deal.

When I got home I checked the coffee order and realized something was not right. There were supposed to be 16 vacuum sealed 1/2 lb. bags, four each for four different coffees, for a total of eight pounds of beans, but there were only 10 bags. Some of them were definitely much less than a half pound but I did not have a scale and so I had no way to know for sure what the total weight was. Three bags were also unsealed and some of the beans had spilled into the larger bag. Two of those bags were the same bean but unfortunately the third one was different so I had no way of knowing which bag, or bags, the loose beans came out of. I dumped the loose beans into the bag that was the most open as that was the easiest one to get them in. I closed the three unsealed bags with spring clips, put everything back in the carry bag, and drove back to the coffee shop.

I was not pleased with the situation, especially the fact that I had to make this extra trip, but I worked through my frustration while driving and was friendly and courteous while I was there. Being upset and nasty to people never accomplishes anything good. Roger was there in addition to Mary and once I explained what we had ordered on Monday evening from Jeff it was obvious that something got lost in translation. They will make it right and we will pick it up late in the afternoon on Monday.

For some time now we have felt that we do not always have Jeff’s full attention when he is waiting on us. Teeko’s has had its challenges over the last couple of years, first with road construction making access to the strip mall more difficult, and now with the opening of a Panera on the opposite corner of the intersection. My sense is that they have struggled financially as evidenced by the fact that they never spent the money for a proper neon sign. As a result the shop is not as visible as it should be even though it is located at a major intersection. Jeff got married last year and they just had their first child in September. With those added responsibilities he went back to work driving a delivery truck for PepsiCo, which has a major plant on the south central side of Howell. His parents, Roger and Mary, have been left to run the coffee shop during the day, which I suspect is not what they intended to be doing in their retirement. Still, they are always very pleasant to deal with and I feel for their situation.

As much as we like Panera, when we still lived in Farmington Hills we tried to patronize a series of small, independent coffee shops but they all failed in the end. Some failed because of mis-management, but ultimately they could not compete with the Starbucks, Panera, and Einstein Brothers stores in the area. Sadly, I suspect this will also be the fate of Teeko’s even though it is a nicer coffee shop than the Biggby’s just down the street. And it’s too bad (for us at least) as we really enjoy being able to purchase a variety of green beans and have them roasted to order.

Back home I finally got to work on the bus around 3 PM. I got all of the old silver colored metal stair edging from the garage and determined where each piece had been installed. I realized that I did not have a good way to cut the new edging nor did I have the time to measure, cut, and install it before it got dark. I really wanted/needed the exposed edges of the tile protected so I decided to reinstall the old edging. Although it had obviously seen heavy use over the years it was still serviceable. Of equal importance was that it was already cut to approximately the correct length and angles. I checked that the holes on the new edging would fall in different places than holes in the old edging. That was the case, so I held each piece in place and drilled a small pilot hole at every third hole. I changed to a different bit to drill through the metal that secures the edge of the plywood bus floor and then screwed each strip of metal edging in place. The new edging will cover the holes from mounting the old edging.

This was the only work I was going to get done on/in/around the coach today. Linda had called by this point to let me know she was heading home and was going to stop at Meijer’s along the way. As soon as she got home she started making three batches of granola. She is going to make and freeze as many batches as she can fit in the freezer so we can enjoy this fabulous granola well into winter.

While Linda made granola I worked at my computer cleaning up old e-mail. Dinner was vegan Pad Thai; not like the real thing, of course, but it was easy, hot, and tasty enough. We had some small oranges for dessert. I worked at my desk for a while after dinner deleting old e-mails. I quit at 8 PM to watch a few TV shows and work on this post.