I set my alarm for 5:30 AM and got up when it went off. I got dressed quietly, fed the cats, refilled their water fountain, and took my allergy pill and B-12 vitamin. I used a plastic bag to pack a change of underwear and socks, a basic oral hygiene kit, my iPad, my checkbook, and my phone charger cable. I loaded my travel bag and walnut pieces into the car and then checked the mousetraps in the pantry. One of them had two mice in it. It was still pitch dark outside so I drove to the end of the new driveway, parked with my headlights pointing across the road, took the trap to other side of the road, and released them. They went scurrying off into the thick undergrowth of the woods and I drove back to the house. I left the trap on the front porch and went inside to wash my hands.

I finally left on my road trip to Indiana at 6:20 AM. I needed fuel so I headed south on Hacker Road and stopped at the Shell Station on Grand River Avenue at I-96. There is a Dunkin Donuts co-located with the station so I got an extra-large coffee and was on my way. I decided to head east a couple of miles on I-96 and then south on US-23 to Ann Arbor where I picked up I-94 west. I took I-94 as far as I-69 and then headed south. Somewhere along this segment I realized I had forgotten the box with the two swivel ring bearings. That meant I would not be stopping at Coach Supply Direct in Edwardsburg, Michigan to return them, which would save me time but necessitate getting them back to Josh another time and/or another way.

The change in plans would loosen up my schedule a bit but I still had four stops to make and was anxious to make time. I stayed on I-69 south into Indiana and then took the Indiana Toll Road (I-80/90) west. Traveling west there is one travel plaza between I-69 and the SR-19 exit. I stopped there to use the restroom and get another cup of coffee. Back in my car I called Josh to let him know I would not be stopping by his shop today in Edwardsburg. I then called Linda to update her on my whereabouts and change in plans. She said she would take care of getting the box with the swivel ring bearings ready to mail.

The weather was overcast, drizzly, cool, and windy when I left this morning. The winds were out of the west so I had a crosswind or a headwind for the entire trip down. By the time I reached Indiana I had driven out from under the cloud cover. The temperature remained very cool but the sunshine was refreshing.

My first stop was A-1 Upholstery in Elkhart, Indiana. Much to my surprise Terry had used the exact same fabric for the filler cushion that we had her use for all of the other ones, so it was a perfect match! I got a call from Josh while I was there and called him back as soon as I left, but got his voice mail.

My next stop was at Pat and Vickie Lintners’ house, about three miles from A-1 Upholstery, to pick up a critical accessory piece for the built-in Nutone multi-function kitchen appliance. We have a functional power base built in to our kitchen counter in the bus but only had the blender attachment. Vickie gave us a number of other attachments at a rally back in September but many of them required a right angle tower adapter. She had found the adapter a few weeks after the rally.

From Pat and Vickie’s I backtracked to the main north-south road, went south back over the St. Joseph River, and headed west on Old US-33 (Lincolnway). I got a call back from Josh and he said to stay on my current road all the way to the Mishawaka bypass and then head south to US-20. From there I was on familiar road as I headed west to US-31 south. Michele Henry from Phoenix Paint had called while I was at Pat and Vickie’s and I let it go to voice mail. I called her back when I was done talking to Josh. They had both called me with some recent scuttlebutt about a service facility in Elkhart where friends of ours had some major remodeling work done on their vintage bus, but it was also a chance to catch up on things in general and helped pass the time as I drove.

I stopped in Argos for fuel and called Bill Tharpe with an ETA of 12:30 PM. I then called Jarel to let him know I would be there by 1:30 PM. Butch had driven me past Bill’s place once some time ago so I had a fairly good understanding of where it was and what it looked like; not that I needed it. Given the address my Garmin 465T GPS unit took me right to Bill’s place on Mexico Road south of Mexico and north of Peru. Sounds like I was in Central America.

Bill was outside waiting for me and we unloaded the antique SUN Electric Distributor Tester from my car and into Butch’s truck, which Bill had for the winter. He was headed to his building in Wabash, where he has a paint booth, to repaint the truck so we did not chat for very long. Besides, I still had one more stop and it would take at least a couple of hours.

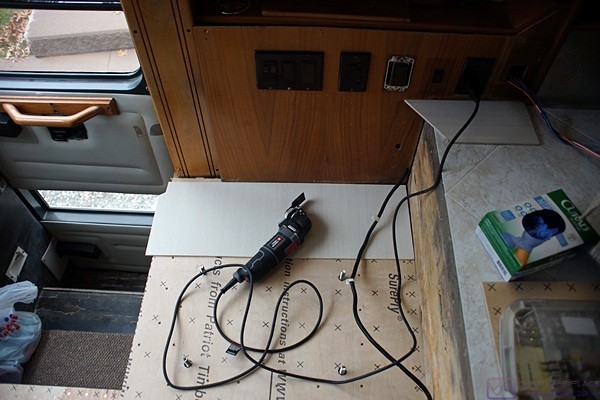

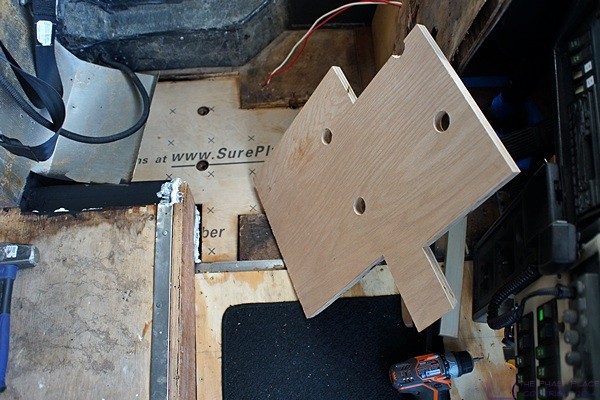

A couple of miles on down Mexico Road I headed west on US-24 towards Logansport and arrived at Jarel Beatty’s cabinet shop at 1 PM. Jarel was not expecting me until 1:30 so he was in the middle of cutting dados in side panels for a tall cabinet. When he finished that task he switched to a regular blade in his table saw to work on my pieces.

We selected the most suitable pieces of walnut from among the ones I brought. He ripped two pieces, one 2″ wide and the other 2-1/16″ wide, and crosscut them to 19-11/16″ long. He then ran them through his shaper to round off the edges. He changed the blade on his table saw, reset the depth of cut, and set the fence to cut off the amount of material I had marked with blue painter’s tape on the bump out for the passenger side HVAC duct cover. With the sawing done he sanded the two new pieces and then sprayed them with a Sherwin-Williams pre-catalyzed lacquer. He let the first coat dry for 15 minutes and then lightly sanded it with 220 grit paper to knock down tiny bubbles and splatters. He then applied a second coat. It was remarkable to see how it changed the appearance of the wood. Jarel described it as being like “putting water on a rock” and I thought that was an apt description.

After another 15 minutes the pieces were dry enough to be transported without damaging them. I wrapped things up with Jarel, including finally remembering to get all of my drawings back, and was ready to leave at 3 PM. The GPS said I would be home by 7 PM, quite a bit earlier than I expected when I left this morning.

I had smooth sailing until I encountered a major traffic jam on I-96 eastbound just east of US-127 on the southeast corner of Lansing, Michigan. It took 45 minutes to go three miles and I was sitting at about 1/8 tank of fuel. Ugh. There turned out to be multi-car accidents in two separate locations about a mile apart plus a car stopped in the right lane that appeared to have run out of fuel. What a mess.

Once I was clear of the accident area it was clear sailing once again. I stopped at the Marathon station at the Fowlerville exit (#127) for fuel and checked out the truck pumps. Although there were lots of semi’s parked there for the night I was disappointed to find that the back lot was in as bad a shape as the Mobil Truck Stop at exit 117. Still, the round trip from our house would be 20 minutes shorter and it was an alternative place to get fuel. The closest place to our house where we can fuel the bus is actually the Marathon station on Grand River Avenue at I-96 in Brighton, which has truck pumps around back, but we have some low branches in the southbound lane of Hacker Road just before we get to Grand River Avenue, so we tend to avoid that route and that stretch of Grand River Avenue is often very busy and not someplace I want to be with the bus unless it is later at night.

I checked the mousetrap in the pantry when I got home and we had caught yet another mouse. I unloaded the car and then took the mouse trap to the end of the new driveway and released it across the road as I had done with the previous four. As I walked down the driveway it was obvious that Phil had been here with his bulldozer, which Linda confirmed over dinner.

The “parking pad” area is now presumably level but it was definitely not flat as it had deep marks from the bulldozer treads and ridges where the gravel had not been completely smoothed out. The top inch or so also seemed very loose. I don’t think Phil is done working on the project as he still needs to spread straw over all of the topsoil that he placed, graded, and seeded the other day. I suspect that he still needs to compact the gravel one last time with his track loader but I won’t know for sure until I can talk to him.

Dinner was chili and crackers; simple but delicious. It had been a long day but I had taken care of four things in one trip, three of which were directly related to the bus and two of those of a somewhat critical nature. We were both off to bed not long after dinner. Tomorrow was our weekly ham radio breakfast so we would have to be up early to get there on time.