Linda planned to go to the bakery today but decided yesterday to stay home and help me instead. Based on the 10-day forecast this looks like our last decent weather day to work on the bus and we wanted/needed to make the most of it.

We had breakfast at 8 AM (granola with blueberries and a banana) and had a cup of Stash China Black tea. I had a text message from Kristine Gullen regarding getting together with her and Jim on Saturday and replied in the affirmative. We finished our tea by 8:30 and got to work.

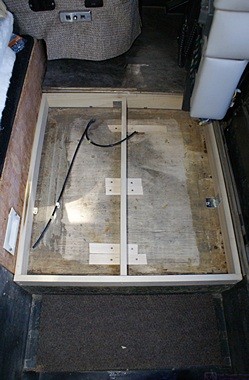

I really wanted to finish tiling the cockpit of the bus, or at least as much of it as we could. That meant cutting and fitting tiles for the stair treads and risers and the two side walls of the entry steps, gluing them in place, and then grouting all of them. We needed to mount the table if possible and I also needed to build a new step for the platform. That was a lot to get done in one day and even before we started I doubted that we would get it all done.

When we opened the bus we were surprised to find that the tiles on the walls of the platform had slipped all the way down to the floor tiles. Obviously I should not have removed the spacers right after installing the tiles and should have to left them in place for any horizontal grout spaces on vertical surfaces. Oh well, not much to do about it now.

Keith called to see if he should come and mulch the leaves one last time. The weather the last few days had been very nice, unseasonably warm and dry. Today was also a beautiful day but the forecast going forward was for much cooler and wetter conditions, so this was an ideal day for our last lawn mowing of the 2015 season.

We measured and cut the tiles for the face of the platform and out to the door. At that point I evaluated what I needed to do to complete the job. Basically, I needed to cut all of the tiles for the entry steps and walls and then install them from the bottom up. Every piece of tile was going to be smaller than a full 16″x 16″ tile and custom cut so even though the square footage was not that much there would be more pieces than usual and it was obviously going to take quite a bit of time to get all of the pieces ready to install. I thought we could be ready for adhesive in two hours but Linda figured it would be at least three. It also meant working with the door open which would make it difficult to keep the interior as warm as we needed.

Phil showed up with his excavator and a dozen bales of straw. I knew the excavator was for a different job as he did not have anything left to do at our place that required it. He was here to finish covering the topsoil and grass seed with the straw. We took a break to go talk to him and confirmed that he was done with the driveway and French drain projects except for the straw. He staged the bales where he needed them but said he had to leave to dig a perk test hole at 1:30 PM and would be back mid-afternoon to finish spreading the straw around.

Linda suggested that we go ahead a grout all of the tile we had already installed. I was more emotionally invested in completing the tile work than Linda but had to agree that this was the prudent thing to do. Until the tile was grouted we could not reinstall the accelerator, the steering column shroud, the seat bases, and the seats, so grouting the tile was clearly a critical path item and that is what we did. It was after noon by the time we finished so we took a break for lunch. Phil had taken off by this time to go dig the test pit.

Lunch was grilled vegan Italian sausage on a bun with mustard and relish and black grapes on the side. Keith finished up mowing the yard while we were enjoying a cup of Rooibos tea. We paid him and chatted about next year. I gave him our approximate timeframe for returning home from Florida and asked him to go ahead and start mowing next spring whether or not we were here. We have had Keith take care of our lawn since we bought our house in the country and he has been very good about doing that when we are away and allowing us to catch up with him when we get back.

By the time we got back to work on the bus it was after 1 PM and I had to concede that we were done working on the tile until next spring except for cleaning them, which had to wait until tomorrow as the grout has to cure for 24 hours before final cleaning. With that decision made we considered what else needed to be done and in what order.

The first order of business was painting the two front seat bases black. We spread out painter’s plastic on the driveway and taped it down. We set the bases there and then masked off the top portion with the swivel bearings and mounting bolt. We wire brushed the bases to remove rust and then went over them with a sanding sponge. I used a cleaner/degreaser and water to clean them and then gave them a coat of black rubberized undercoating paint.

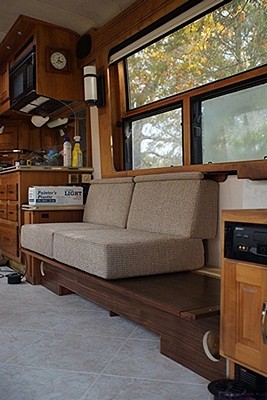

The next order of business was getting all of the tools and materials that we no longer needed out of the bus to give us room to work on other things. On Saturday I re-installed the bump out on the walnut cover for the passenger side HVAC duct. The duct needed to have two 4″ holes drilled in it to match the holes in the metal duct, so that was the next task. I measured very carefully and transferred the measurements to the face of the cover with equal care. Even so, I was off slightly and had to use the sheet metal nibbler to enlarge the bottom of each hole. At least I had a relatively straightforward way to fix this problem; I am not always so lucky.

With the holes enlarged we put the cover in place. The 4″ round plastic registers fit through the wood into the duct but not all the way due to two tabs. I trimmed the tabs off using the Porter-Cable oscillating saw and trimmed a little bit off of one of the outer mounting flanges to make it fit flush. I drilled holes through the two mounting holes on each register using the #5-6 self-centering drill bit and secured them with #6-5/8″ SR screws. We then removed the two temporary black plastic registers from the front of the built in sofa. I trimmed the tabs off of two new brown ones and installed them using the same procedure as the first two.

In the grand scheme of things getting the cover in place and the four registers installed was a small task but it needed to be done and stood in the way of other things. The cover has been stored on top of the two front seats, which have been lying on their backs on the kitchen floor of the bus for weeks. We plan to re-install the seats late tomorrow afternoon.

Two more small, but critical, tasks were securing the pull-out pantry and the refrigerator. I have assumed for quite a while that we would secure the pantry for travel with some form of sliding latch but had not thought about it in any detail. We also needed to secure the refrigerator but I had not thought about this in any detail either. As we pondered the pantry latch it slowly became obvious that we did not have enough wood for a strike plate to receive a pin and we did not have two unobstructed surfaces that were in the same plane, which would be required for the kind of latch I had been thinking about.

As for the refrigerator, one of our bus nut friends secured their unit by running mounting bolts (machine screws) through the floor of the cabinet above the fridge and threading them into the unused tapped holes provided for the upper door hinge (if it was reversed) . After looking at it for a while we realized that we could attach a section of small angle to the inside of the right alcove wall with the other side just against the face of the fridge case but not over so far as to interfere with the door gasket. My measurements indicated that a 1/2″x3/4″ angle would be just right. It looked to me like two 12″ pieces, one by the freezer door and one by the bottom of the fresh food compartment door, would be more than adequate to keep the refrigerator from rolling out as it cannot shift sideways or twist due to the aluminum angle on the left/hinge side at the floor.

About this time Phil returned in a red pickup truck. He finished distributing the straw and loaded three unused bales into the back of his truck. He pulled up in the main drive and we invited him into the bus to see what we had been working on all summer. It is always a pleasure working with Phil. If/when we build a barn we will have him do all of the site prep and finish grading. He will figure out the final cost for the driveway extension and French drain and send us an invoice.

Linda prepared an easy but tasty dinner consisting of a nice green salad, mixed frozen vegetables (corn, peas, and carrots) suitably reheated, and mac-n-cheese that was both dairy-free and gluten-free. After dinner we went to Lowe’s and The Home Depot. At Lowe’s we bought a 1/16″ thick 1/2″x 3/4″ aluminum angle and three 8 foot lengths of brass colored nose edging but did not find a latch that we liked. At The Home Depot we bought some screws for securing the handle on the front of the pull-out pantry and a solid brass door stop to keep the pantry in place. The door stop folds up when not in use and should work to keep the pantry closed while traveling.

Although the new Panera on the southwest corner of Grand River Avenue and Latson Road was finally open for business we stopped at Teeko’s Coffee and Tea on the northeast corner of that intersection. Jeff was there and took our order for eight pounds of coffee beans. We got two pounds each of Ethiopian Yirgacheffe, regular and decaffeinated, the Seattle Blend (regular), and the Sweet Dreams blend (decaffeinated). They will roast the beans and then let them outgas for a few days before vacuum sealing them in half-pound portions. This allows us to take them with us in the bus and keep them very fresh until we are ready to use them and to change what we are drinking more often.

We got home just after 8 PM and took our iPads downstairs to use while we watched our Monday evening CBS TV programs. We caught the weather forecast and then headed to bed. It looks like we will have two more days with unseasonably high temperatures near 60 degrees F but with intermittent rain and then a serious cooling trend with highs this weekend barely above freezing. Our time for working on the bus and being in Michigan is definitely running out.