2014/10/23 (R) Close Encounter of the 1st Kind

My two main bus projects today were the lighted handle by the entrance door and the Progressive Industries remote display installation. The lighted handle needed new machine screws and some additional gasketing on the upper securement. It turned out that all five of the screws that I removed were stripped to a greater or lesser extent. After trying several different screws I concluded that the threaded holes must be messed up. Butch loaned me a 10-24 tap and I used it to re-tap all five of the mounting holes. I cut two additional pieces of the vinyl shower pan liner and trimmed them to fit just inside the upper securement. That allowed the piece to be reattached to the body using the 10-24 stainless steel screws I bought last night without causing interference with the LED bulb.

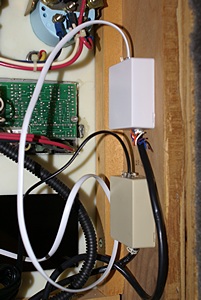

Some time ago I bought a remote display kit for our Progressive Industries Energy Management System (EMS). The kit consists of a second display unit and a selector switch unit. I mounted the selector switch in the utility bay in place of the display unit, moved the display unit to the left, and connected it to the switch with the short cable provided in the kit. I routed the long cable from the switch through the bay to the other side by the Aqua-Hot and fed it through a small hole into the electrical bay, which is the next bay going towards the front of the coach. I temporarily mounted the remote display in the house panel. I then repeated the work I had done yesterday to relocate the Magnum inverter/charger remote. This time I used serial cable #1, removed the DB-9 connectors from each end, and connected the wires on each end. The difference from yesterday is that Progressive Industries wires their cables so that pin 1 of the RJ-11 on one end is wired to pin 1 of the RJ-11 on the other end. That meant I had to keep the wire colors the same between the two surface-mount phone jacks, i.e., black-to-black, red-to-red, green-to-green, and yellow-to-yellow, rather than cross wiring them like I did yesterday.

Butch’s major focus today was the ITR Oasis Combi. He and Fonda worked for much of the day running new diesel fuel lines. By late afternoon I was done with my projects and went to work on the fresh water plumbing for the Oasis. Prior to the last couple of weeks I had not worked with PEX tubing and fittings. Butch has a crimper that he showed me how to use. By the time we quit working to have dinner we had the fresh water tank connected to the inlet of the Shur-Flo 4048 pump, the outlet of the pump connected to T-fitting that supplies cold water to the house and to the Oasis Combi inlet, and the outlet of the Combi connected to the line that supplies hot water to the house.

For dinner I fixed a salad, a Thai Kitchen mushroom noodle soup bowl, and a bowl of fresh strawberries for dessert. I took everything in the house and dined with Butch and Fonda. After dinner I went back to the coach to try and straighten things up a bit. I must have opened the cabinet door under the kitchen sink a dozen times to throw away food scraps, product packaging, and paper towels. I had bundled up the various recyclables and opened the cabinet to remove the trash bag when the mouse jumped out and ran under the passenger side couch.

I say THE mouse because I presume it is the mouse that has obviously been in the coach recently based first on getting into my loaf of bread and then finding a nest where none had been previously. It was a cute little dark gray field mouse, not more than two inches long (without its tail), but I am going to have to find a way to catch it and remove it. I will set a live (no kill) trap next week and see if I can find it a nice field to live in somewhere far away from Butch and Fonda’s house and both of our buses.

It was still in the upper 40s and rather pleasant outside so I straightened up the back of my car rather than wait until morning. After retiring to the guest bedroom I organized most of my clothes. I should be packed and on the road about an hour after I get out of bed in the morning.

2014/10/24 (F) Around the World in 80 Days

As much as I have been traveling back and forth between Michigan and Indiana I feel as if I could circumnavigate the world in 80 days but today my “journey of a thousand miles” began with a 260 mile trip home. I was up a little before 8 AM and finished packing all of my stuff in the guest bedroom and loading it into the car. I gathered up some last minute laundry, foodstuffs, and recyclables and put those in the car as well. I sat and chatted with Butch and Fonda until 9:10 AM and then said farewell until Sunday evening. I pulled my car out its normal parking spot at 9:15 AM and headed east on SR-16. I followed my usual route home from there: US-31 north to US-20 east to CR-17 north to I-80/90 (Indiana Tollroad) east to I-69 north to I-96 east to M-59 east to Hacker Road south and then home.

Our friend Kate had contacted us yesterday to see if we were available to go to the Meadow Brook Theater to see a live theatrical performance of an adaption of Jules Vern’s Around the World in Eighty Days. Her cousin is working as an intern at the theater this season and was able to get courtesy tickets. Linda was feeling well enough to go so we left early and stopped at a Panera on the way over to the theater where we met up with Kate. The performance was very good and we thoroughly enjoyed it. We wanted to have coffee together afterwards, but by the time we met her cousin and chatted for a while it was late and everything was closed. Besides, we had an hour’s drive to get home and Kate probably had at least 90 minutes.

2014/10/25 (S) Here And There

Linda slept in to rest and try to recover from her cold so I went to the SLAARC Ham Radio Club Breakfast by myself. She was awake by the time I got back and feeling well enough to run errands with me. We stopped at Recycle Livingston and then picked up our new natural gas fireplace logs from Country Squire in Howell. We got the business card of the independent technician who does installations for them and gave them a call to set up an appointment. I left a message and they called us back later. We stopped at our Bank of America branch enroute to Staples in Brighton in search of a larger size of graph paper, but they did not have the size I wanted. I need larger paper to draw accurate designs for the custom desk/pantry and printer stand/table that we want to have made for our converted bus. We fueled up at the Brighton Meijer’s and then bought groceries. We needed a new coffee maker but decided not to purchase one until we had checked online.

Back home we searched for coffee makers in a white finish rather than black/stainless. There were only a few choices and one of them was a Mr. Coffee programmable model that was available at Bed, Bath, and Beyond. As long as we were looking for things online we found a pad of 50 sheets of 17″x22″ graph paper with a 1/4″ grid pattern and added that to our Amazon Prime shopping cart. We also added a Camco RhinoFLEX RV sewer hose kit and various accessories.

Linda had arranged for us to meet John and Diane at Camellia’s in Farmington Hills for dinner at 6 PM. We left the house around 4 PM and stopped at the Brighton Bed, Bath, and Beyond to get the Mr. Coffee coffee maker. We stopped at the Meijer’s in Wixom and picked up the filters and then stopped at J. C. Penney’s at Twelve Oaks Mall for some necessary clothing items. We headed into Farmington Hills but were still early for dinner so we drove through our old neighborhood, which is very close to the restaurant. Our former across-the-street neighbor, Dan, was working on a car in his driveway so we stopped to chat. While we were there the young man who bought our house arrived home on his motorcycle. He never removed his helmet before putting the bike in the garage and shutting the door, so we never actually saw him. Our daughter handled the closing in July 2013 since we were in Wyoming at the time, so we never meet the buyer or his parents. He has apparently been a very quiet neighbor who keeps to himself.

We got to the restaurant shortly after 6 PM and John and Diane were already seated so we did not have to wait for a table. We had the veggie fajitas, our standard choice at this particular Mexican restaurant. While we were dining our friends, Jim and Kristine Gullen, came in and sat in a booth near us. When we were done with dinner John and Diane headed to their house (nearby) and we lingered for a few minutes to chat with Jim and Kristine before joining them. Diane had bought some Coconut Bliss Chocolate with Salted Caramel non-dairy “ice cream.” It was the best vegan ice cream we have had. By 10 PM we were all having trouble staying awake so we said farewell and headed for home and went quickly to bed.

2014/10/26 (N) Pack and Go

We both slept in this morning, the combined effect of being tired (both of us), sick (Linda), and having taken Tylenol PM last night (both of us, again). In spite of her cold, Linda wanted to cook something for me before I took off again for Indiana, so she made her wonderful vegan blueberry pancakes for breakfast. We used the new coffee maker and, as expected, the coffee tasted the same as with the old one.

After breakfast we sorted and folded laundry (we have such exciting lives) and I selected and packed the items I needed for the week ahead. I had not copied photos from my laptop to the network drives since October 10th so I took care of that. I also made more careful measurements of the dimensions of our color laser printer to use in refining the design of the printer cabinet for the bus. Likewise, I took measurements of our Dewalt air compressor as I plan to build a wooden divider for the back of the Honda Element that will secure it on the floor and create space next to it and above it for storing other things. Obviously the two rear seats will be removed when this insert is in use.

By 2 PM I was ready to load the car so Linda helped me with that task. I pulled out of the driveway at 2:16 PM and followed my usual route to Indiana: Hacker Road north to M-59 west to I-96 west to Lansing Road south to I-69 south to I-80/90 (Indiana Tollroad) to CR-17 south to US-20 west to US-31 south. I exited US-31 at IN-25 (Rochester), topped off my fuel tank and then picked up fresh greens and fruit at the Kroger. I headed south on IN-25 to Fulton where I took Aitken Road east to Meridian then headed south to SR-16 and finally headed east to Twelve Mile.

Butch and Fonda had their family holiday gathering today. They had 27 family members in attendance during the day and for dinner but by the time I arrived (7:45 PM) everyone had left except Brittiny and Rock, and they departed while I was unpacking food and storing it in the coach. I moved all of my clothes and technology into the guest bedroom, like I always do, and then visited with Butch and Fonda for a while before retiring to my room for the evening. If the weather forecast holds true we have two unseasonably nice days in store on Monday and Tuesday and the rest of the week doesn’t look too bad either. We have a lot to do and could use some favorable weather.

2014/10/27 (M) Heat and Light

We had an unseasonably nice day for working outside. It was already in the upper 40s when we got up and made it in to the 70s under partly cloudy skies with breezes from the southwest. I was up before 8 AM and had my usual granola, orange juice, and coffee for breakfast and then got to work.

Butch worked most of the day on assembling the two fan-coil heat exchanger units that will get plumbed into their ITR Oasis Combi diesel-fired hydronic furnace to provide heat to the house portion of their converted bus. While he worked on that I worked on replacing our patio light. The ballast on the old one was no longer working and the way the unit was designed it could not be replaced. Butch happened to have an identical unit, so I used it as the replacement.

The old unit was not removed from the coach when it was painted. This was a nice idea at the time as it provided a paint seal on the top and both sides where the unit met the side wall of the bus. Unfortunately, removing the unit required me to cut the paint seal with a very sharp knife. The unit was secured with two screws, but it was stuck to the side of the coach with a generous amount of automotive putty. Most of it came off with the fixture, but not all, so after I cut the two wires and removed the fixture I had to carefully scrape the rest of it off using the thin end of a wood shim.

I checked the voltage at the two wires coming out of the wall and I definitely had 13 VDC controlled by the same switch that turns the lighted entrance handle on and off. I prepared the back of the new fixture using new automotive putty to create a seal all the way around the back at the outside edges. I also placed a ring of putty around each of the screw holes in the back and the access hole for the wires. I attached shielded spade lug disconnects to all four wires, held the fixture in place, and connected them. I pressed the fixture into position, lined up the screw holes, and secured it. I put the two F8T5 florescent tubes back in, snapped the cover back in place, and made sure the on/off pushbutton switch on the bottom was in the on position. I then applied a bead of NAPA RTV Black Silicon Rubber sealant along the top seam and the two sides. (Sorry Michele, but I had to make sure it was not going to leak.)

The switch that controls this light is one of three in a 3-gang box next to the passenger seat and is the one closest to the entrance door. I had removed the cover plates last week so today I took another look and it appeared that the other two switches did not have any wires connected to them. I removed them and that was indeed the case. I think tomorrow I will re-wire this so the first switch controls only the lighted entrance handle and the second switch controls only the patio light. If I cannot figure out something to control with the third switch I will probably leave it out and get a new cover plate that has two switch openings and a blank, assuming I can find one.

With the patio light project done Fonda helped me remove the fan belt and the two A-C compressor drive belts from the engine in our bus. We put the two compressor drive belts (NAPA CG-96) back on but reversed their position. The inside one seemed loose compared to the outside one last week and we wanted to see if switching them would fix that problem. We then installed the new fan belt that I ordered/received last week.

I started the main engine and let it run for a while on high idle with the air-conditioning turned on to put some load on it. The CG-96 that was now on the outside of the pulley still appeared to be looser than the other one, so I think I will order a replacement set. The new fan belt ran very smoothly. I turned the A-C off, dropped the idle down, and shut off the engine. I started to close the rear access hatch but found that it was stiff and made a sound like an elephant trumpeting. I sprayed some WD-40 on all the hinges and on the piston rods for the air springs. I then put a small amount of NAPA Syl-Glide on the piston rods, worked them up and down a few times, and wiped off any excess. The hatch now opens and closes smoothly and quietly with less effort.

While I was lubricating the hatch Butch was using a pressure washer to clean the radiators (heat exchangers) for their fan-coil units. As long as he had it out, he sprayed around all of our front windshield seals while I looked for leaks inside. We found three for sure. One was in the upper inside corner of the lower driver-side windshield between the center pillar and the seal. The second one was in the lower outside corner of the upper driver-side windshield between the seal and the glass. We were not able to identify the point(s) of entry for the third one but it appeared to be somewhere above the upper windshields near the center pillar, a least that was where the water was coming in on the inside. I cannot see the underside of the front cowling in that area and there are lots of places water could come in: five front marker lights, two upper windshield mounts, and perhaps a dozen screws on top of the front roof holding various things down.

Leaks are annoying and potentially destructive so I am still pondering what I want to do. We have new windshield seals but have had trouble finding someone locally to install them. For one thing, the bus really needs to be inside for that work and most glass shops, including ones that work on “semi tractors,” do not have overhead doors high enough for the bus. I may make judicious use of the NAPA RTV Silicone Rubber sealant or I may just use black tape as a temporary fix.

When we were done checking the windshields I used the pressure washer to clean off the coach as best I could. The last time it was cleaned was right before we left Williston Crossings RV Resort in early April and it had accumulated a few miles, bugs, and dirt in that time.

Because the weather was so nice Butch decided to replace a short section of badly deteriorated coolant hose on their engine rather than risk having it fail on the road. He shut some valves to isolate the engine from the coolant lines that provide heat to the coach and drained quite a few gallons out of the engine (almost three 5-gallon buckets). The old hose turned out to be extraordinarily difficult to remove. The new piece was no easier to get in and required modification of two parts. This was definitely not a job you want to do on the side of the road in any kind of weather.

While Butch and Fonda worked on the coolant hose I tinkered in the dashboard area of my bus. First I replaced a couple more bulbs in illuminated switches. I then pulled the CB radio out of the dash to see how the coaxial cable (transmission line) was marked. That allowed me to identify the other end in the old ceiling-mounted TV cabinet behind the driver’s seat. I also looked around in that cabinet for the other end of the coaxial cable that was once connected to the antenna for in-dash AM/FM radio/cassette/CD player. I did not see anything that looked right, so I pulled the radio out of the dash (actually the whole panel along with four switches) to get the identifying marks off of it. Even with that information I was not able to locate the other end of the cable.

By that point it was 6 PM and we had weather approaching from the southwest. Clouds had moved in, greatly reducing our natural light, and gave the first indications of the rain that was forecast for the evening hours. I will look again for the radio antenna cable tomorrow as I have a TuneTrapper antenna that I want to install on the underside of the front roof via the old TV cabinet and I need to plug it into the cable that goes to the radio.

I had a small glass of Moscato while I prepared my dinner. I fixed a salad of power greens with peanuts, dried cranberries, and fresh diced onions and finished a bottle of Ken’s Sweet Vidalia Onion dressing. I grabbed a can of Amy’s “No Chicken Noodle” soup, some crackers, my jar of peanut butter, and some ICE brand water and went inside to eat with Butch and Fonda. I returned to the coach after dinner, cleaned up my dishes from the day, and bagged up my recyclables. We bought a small container on Saturday that is intended for storing pet food but it has a gasketed lid with a snap latch that I thought would make a nice mouse-proof kitchen trash can. (I figure the mouse will leave if it cannot get any food.) Alas, the container does not fit in the base cabinet under the kitchen sink so it will likely end up being used for its intended purpose after all.

2014/10/28 (T) Under the Bus

In corporate life “getting thrown under the bus” is not a good thing, but if you are the owner/builder/maintainer of a converted highway coach, getting under the bus will eventually be a necessity. Today was finally my day, but not until mid-afternoon.

The forecast for today was for rain in the morning tapering off to zero by noon and then turning sunny; and that is exactly the day we had. Knowing that the morning would be wet, I took a couple of Tylenol PM last night and slept in a bit later than normal. After my usual breakfast of granola, orange juice, and coffee, with some spicy V8 thrown in for good measure, I set to work on the interior of the old TV cabinet located above and behind the driver’s seat.

Yesterday I pulled the CB radio and the AM/FM radio out of the dashboard and identified how the coaxial antenna cable for each one was marked. I located the cable for the CB in the TV cabinet but was not able to find the one for the AM/FM radio. I got my twin tube florescent worklight and rigged up a couple of zip ties with mounting tabs to hang it from. I looked again this morning but still could not locate the AM/FM radio antenna cable. Rather than waste time not finding it I decided to organize the inside of the cabinet which has had an outlet strip, an OTA TV antenna controller, the Wi-Fi Ranger POE adapter, DC power supplies, and a mess of cable that has been lying around in it for a couple of years now.

Using the tab mount zip ties I coiled each cable and secured it to one of the two side walls. The OTA TV antenna cable (signal and control) was very long, so I wound it around a 5-gallon plastic bucket to make a nice round, large coil. The outlet strip had mounting slots on the back, so I mounted it to the wall on the lower half of the back of the cabinet. The upper half of the back is open to the area above the driver and entrance stairs and under the front cap of the roof.

Late in the morning I took a break from the TV cabinet work and helped Butch cut access panels out of a 1/8″ aluminum sheet that will cover the inside of their entrance door. We tried using a sabre saw but the only blade we had was not sharp enough or was the wrong type. We used his Ryobi cordless reciprocating saw with a metal cutting blade and it made much quicker, and surprisingly clean, cuts. I then used Butch’s angle grinder to round the corners of the sheet and remove burrs from all of the cut edges.

I stopped for lunch around 2 PM and enjoyed a hummus and onion sandwich. By the time I was done the day was as warm and sunny as it was going to get so I decided to scoot under the bus and measure the ride height linkages. This was the first time I have been under the bus. Please note that the bus was supported on four stands that Butch made for me out of 1/2″ steel plate and 4″ square steel tube with 1/2″ thick walls. In other words, the bus was not supported by the tires and air springs so the bus would not move if there was a failure in one of those components.

The linkage in the front was easy as I could slide under the bus just in front of the driver side steer tire and then sit up between the front tires with lots of room to work. The linkage is directly above the center of the front axle and connects the axle to a lever arm on an air valve that determines the amount of air that goes into the front airbags (when in drive mode), and thus sets the suspension at “ride height.” Butch wanted me to remove the linkage but I chose not to. As it turned out I should have and will probably slide back under the front tomorrow and remove it.

The rear linkages were much more difficult. First of all, there are two on them, one for each end of the drive axle. They are located just inside the body panel directly in front of the outside dual drive tire and are covered by a protective shield. The shields are bolted on at four points, none of which are easy to reach and one of which ultimately required me to get under the rear end of the bus. Access is much tighter here because of: 1) The dual drive tires on each end of the drive axle; 2) The drive axle carrier, and; 3) The exhaust pipe for the Aqua-Hot which runs under the bus from the passenger side to the driver side where it ends up next to the exhaust pipe from the generator. I was able to scoot under the bus from the passenger side just in front of the drive tires, but just barely, and once I was under far enough to sit up there was much less room to work compared to the front. Because of the difficulty of getting to the linkages to make an accurate measurement of the center-to-center distance between the mounting bolts I went ahead and unbolted them and removed them.

The linkages consist of a length of metal rod approximately 1/4” in diameter with a rubber bushing on each end that looks a bit like and eye-bolt. The rubber bushings slip over the ends of the metal rods and are secured with band clamps. They appear surprisingly fragile given the critical nature of their function, and Butch has already had one that was only a couple of year’s old break on their coach. He ordered metal versions in both left-hand and right-hand threads and is going to assemble replacements using threaded rod and stop nuts. With a left-hand threaded bushing on one end and a right-hand threaded bushing on the other end we will be able to turn the threaded rod one way to increase the distance between the two mounting bolts and the other way to shorten it, affecting both ends equally in the process. The stop nuts will lock the bushings relative to the threaded rod so they do not move in operation. All-in-all this will be a neat little project.

In spite of the lovely weather Butch needed to get to the NAPA store in Logansport before they closed at 5:30 PM. At 4:30 PM I wrapped up my work with the linkages, put all of my tools away, washed up, and grabbed my wallet, cell phone, and shopping list. We got to the NAPA store a little after 5 PM and took care of our business there. We then headed to the O’Reilly’s Auto Parts store for a few other things. I called Linda and chatted briefly with her and was relieved to hear that she sounded, and was feeling, considerably better. Butch called Jaral Beatty to see if he had finished cutting the oak valences for the front of their bus. He had, so we swung by Jaral’s shop to pick them up.

While we were at Jaral’s he ripped a nice piece of 3/4″ thick oak for me to just under 3″ wide. The piece was about 4′ long and he did not charge me for it. I plan to attach this piece of wood to the center windshield pillar and use it as a mounting plate for a compass, flat panel monitor, PressurePro TPMS receiver, and the mirror that is currently mounted at the intersection of the four windshields. I have to do this, of course, in such a way that it does not obscure my vision while driving. From Jaral’s shop we went to Home Depot where I bought a thin (1″ thick), 13″ long, under-cabinet, single-tube florescent, AC powered light fixture. I also got a blade for my Porter-Cable oscillating saw.

When we got back to Twelve Mile a little after 7 PM Fonda started preparing their dinner and I did the same. I had a nice salad of power greens with onions, dried cranberries, and roasted peanuts topped with a sweet and sour dressing. I also had a bowl of Thai Kitchen spring onion soup, some canned pears, and half a piece of pita pocket bread. After dinner I washed my recyclable containers and went back to the coach for a while where I cleaned and dried a few utensils. I then mounted the new light fixture in the TV cabinet. As I expected, it provides very nice illumination for the entire inside of the cabinet.

Depending how the day goes tomorrow I plan to continue working in the front TV cabinet. I would like to mount the TuneTrapper AM/FM antenna and get it connected to the AM/FM radio. Butch’s brother, Tom, is coming over sometime during the day to winterize his motorhome. Butch called and asked him to bring the faceplate from an old Kenwood radio that he had that was very similar to the one in our dashboard. The backlight illumination bulb is burned out on ours. I also need to create an access slot in the door for cables to pass between the back of the flat panel TV (which is mounted to the outside of the door) and the inside of the cabinet. To create this access slot I will have to drill holes centered along a line and then use Butch’s root-zip tool to connect the holes into a slot. The bushings for the ride height linkages are supposed to be in tomorrow, so we will be making a morning trip towards Kokomo to pick them up. Butch is also trying to tap into the engine coolant loop that provides OTR heat for their bus as part of the Oasis Combi installation, so it is likely to be a very full day.

2014/10/29 (W) Outside In

My main project today was once again the front TV cabinet only this time the focus was on cutting a horizontal opening in the door behind the flat panel TV that is mounted on the outside of the door. The approach I used was to drill two 1″ holes, one at either end of a horizontal line, and then use a roto-zip tool as a mini-router to connect the tops of the holes together and the bottoms of the holes together, creating a horizontal slot with rounded ends. The slot is below the horizontal center line of the TV set and offset to the left (as viewed from the front of the TV) to line up with the area on the back of the set where the power, video, and data cables exit downward. The position of the slot allows them to gently bend and pass from the outside of the cabinet to the inside of the cabinet where they get connected. This also allows the cabinet door to be closed and latched with none of the cables visible. It sounds simple but it took me a good part of the day to get it done. We have a second flat panel TV in the bedroom mounted on a similar door that covers another old TV cabinet. Cutting a similar slot in that door is on my task list for tomorrow.

When I wasn’t working on the TV cabinet I spent a few minutes learning how to use an air-powered cutoff tool and giving Butch a break by using it to help cut off a piece of the center tunnel sidewall in their passenger side front bay. Butch is removing this panel in order to gain access to the engine coolant lines that provide heat for the bus when it is underway. He needs to tie a stacked-plate heat exchanger into these lines as part of the ITR Oasis Combi hydronic heating system installation.

Butch spent most of his day working on their Suburban installing a Ready-Brake auxiliary braking system and extra rear lights for towing. I checked in with him from time to time, but he was either in the middle of one-person tasks or had Fonda helping him. Late in the afternoon we rolled his Ryobi belt sander out of the warehouse and used it to sand his two valence boards and my piece of oak that we picked up yesterday from Jarel. We had to change the sanding belt and it took us a few tries to get it right, but it did a nice job on the boards once we had a good piece of sandpaper on it.

By the time we finished it was twilight and very cool. Tom and Tracy showed up about then to winterize their motorhome. There was a locked cover over the fresh water fill connector and none of Tom’s keys would open it. I got a long flat-blade screwdriver and was able to slip it up under the cover and pop the lock. I left the winterizing to Butch and Tom and retreated to my coach to putter and contemplate (and eat) at a lovely 67 degrees F. The Aqua-Hot has been working very reliably, cycling on and off automatically in response to the space and water heating demands of the coach.

Tom brought an old Kenwood car stereo that he got from Butch a while back. Although similar in appearance to our Kenwood dashboard radio, it was not similar enough. The electrical connector on the back of the removable faceplate was in a different location than ours. I had a Singapore Noodles dish in the coach and then made a salad to take into the house and dine with Butch and Fonda. It was after 9 PM by the time we were done eating and I turned in for the night shortly thereafter.